Products & Technology

High Tensile Strength Steel Plate

for Construction Machinery

Features

- High-tensile strength steel plate lineup ranging in tensile strength from 590 to 980 N/mm2

- Available in very high thicknesses, over 100 mm

- HYD960LE and HYD1100LE high-yield steel is also offered for applications requiring exceptionally high strength

- Excellent weldability

- Guaranteed toughness at low temperatures ‒40°C

Examples of Product Characteristics

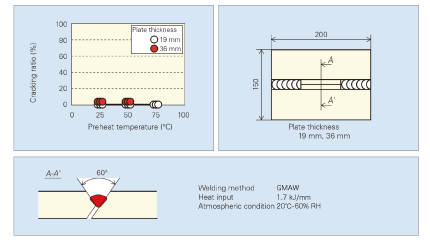

Results of y-groove weld cracking test on JFE-HITEN 780LE

No low-temperature cracking occurred, even at a preheat temperature of 25°C. The ability to reduce preheat temperature enables greater work efficiency.

Table of Grades

| Type/grade | Thickness (mm) |

Ceq. (%) |

Tensile test | Charpy impact test | Heat treat ment |

||

| Yield strength (MPa) t(mm) |

Tenslie strength (MPa) |

Test temperatrue (℃) t(mm) |

Energy (J) |

||||

| Standard Series |

JFE-HITEN 590SA | 6~40 | ≦0.45 | ≧450 | 590~710 | ― | ― | CR or TMCP |

| JFE-HITEN 590SB | -10(t>12) | ≧47 | ||||||

| JFE-HITEN 590SL | 6~32 | ≦0.46 | ≧450 | 590~710 | -40(6≦t≦36) -20(t>36) |

≧27 | ||

| 32.1~50 | ≧430 | 570~705 | ||||||

| JFE-HITEN 690S | 6~25 | ≦0.50 | ≧550 | 690~830 | -10(t>12) | ≧47 | ||

| JFE-HITEN 780S | 6~50 | ≦0.53 | ≧685(t≦75) ≧665(t>75) |

780~930 | -5(12<t≦20) -15(20<t≦32) -20(32<t) |

≧35 | QT | |

| 50.1~100 | ≦0.61 | |||||||

| 100.1~160 | ≦0.70 | |||||||

| JFE-HITEN 980S | 6~50 | ≦0.65 | ≧885 | 950~1130 | -10(12<t≦20) -25(20<t≦32) -30(32<t) |

≧35 | QT |

| LE (high toughne ss series) |

JFE-HITEN 780LE | 6~19 | ≦0.40* | ≧685 | 780~930 | -40 | ≧40 | QT or TMCP |

| 19.1~32 | ≦0.43* | |||||||

| 32.1~40 | ≦0.47* | |||||||

| 40.1~50 | ≦0.53* | ≧685(t≦75) ≧665(t>75) |

780~930 | -40 | ≧40 | QT | ||

| 50.1~70 | ≦0.65* | |||||||

| 70.1~160 | ≦0.73* | |||||||

| 160.1~203.2 | ≦0.75* | |||||||

| JFE-HITEN 980LE | 6~32 | ≦0.58* | ≧900 | 980~1150 | -40 | ≧40 | QT | |

| 32.1~50.8 | ≦0.65* | |||||||

| 50.9~101.6 | ≦0.71* | ≧830 | 880~1080 | |||||

| JFE-HYD 960LE | 6~32 | ≦0.64* | ≧960 | 980~1150 | -40 | ≧27 | TMCP or QT |

|

| 32.1~50.8 | ≦0.70* | |||||||

| 50.9~63.5 | ≧930 | 950~1120 | ≧19 |

※): C+Mn/6+(Cu+Ni)/15+(Cr+Mo+V)/5

other case: C+Si/24+Mn/6+Ni/40+Cr/5+Mo/4+V/14

other case: C+Si/24+Mn/6+Ni/40+Cr/5+Mo/4+V/14

CR: Control rolling

TMCP: Thermo-Mechanical Control Process

QT: Quenching-Tempering

TMCP: Thermo-Mechanical Control Process

QT: Quenching-Tempering

Available in a wide range of strength grades and sizes

This lineup of high-tensile strength steel plate spans a tensile strength range from 590 to 980 N/mm2. JFE also offers two high-yield strength plate products, HYD960LE and HYD1100LE, for applications requiring even greater strength.

The chemical composition of these products was carefully designed to ensure excellent weldability. This steel plate is guaranteed to maintain its toughness at low temperatures, making it suitable for construction machinery that needs to operate under extreme weather conditions.