Cold-rolled steel sheets

Cold-rolled High-Strength Steel Sheet with Excellent Formability(JEFORMA™)

Advantages

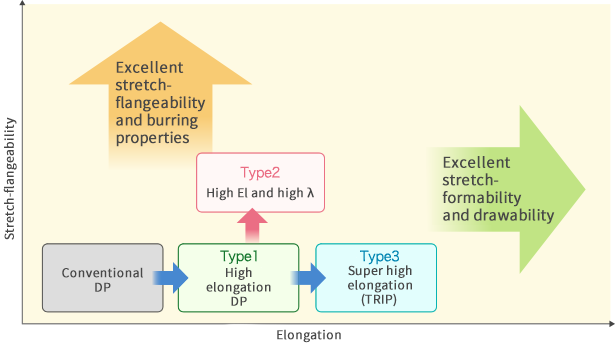

- Customers can select the most suitable formability grade from 4 featured types including the conventional grade in every TS grade.

- Uniform series line-up in the strength grades of 590, 780, 980 and 1180MPa for cold-rolled and galvannealed steel sheets.

- Optimized material design that considers weldability and anti-delayed fracture properties.

- Wide variety of sheet sizes produced.

Product line-up and features

| Name | Type | Features in formability | Suitable parts | |

|---|---|---|---|---|

| Conventional HSS | Conventional DP* | Good bendability required for the stamping to a simple shape | (CR) Bumper, Door Impact beam, etc |

|

| JEFORMA | Type1 | High elongation DP* | Suitable for stretch-forming or drawing parts due to high elongation | (CR) B-pillar upper, A-pillar upper, front member, etc |

| Type2 | High El- high λ** | Suitable for severe stretch-flange forming parts | (CR) Rail outer,Roof cross member,etc (GA) B-pillar lower, A-pillar lower,Side sill outer/inner,Front side member,Floor cross member,etc |

|

| Type3 | Super high elongation (TRIP***) | Suitable for more severe stretch-forming or drawing parts due to extra-high elongation | (GA) Integrated b-pillar, Integrated A-pillar, etc |

|

- *DP:

- Dual Phase steel

- **λ:

- Hole expanding ratio, index of stretch-flangability

- ***TRIP:

- TRansformation Induced Plasticity

Material properties

Typical mechanical properties

| Grade | Type | Name | YS (MPa) | TS (MPa) | Elongation (%) | Hole expanding ratio: λ (%) |

Development stage |

|---|---|---|---|---|---|---|---|

| 590 | Conventional DP | JSC590Y | 390 | 650 | 29 | 65 | Commercial production |

| High elongation DP | 590CR-type1 | 385 | 635 | 32 | 65 | Commercial production | |

| Super high elongation (TRIP) | 590CR-type3 | 400 | 620 | 37 | 70 | Commercial production | |

| 780 | Conventional DP | JSC780Y | 560 | 810 | 19 | 30 | Commercial production |

| High elongation DP | 780CR-type1 | 505 | 820 | 20 | 50 | Commercial production | |

| High El- high λ | 780CR-type2 | 520 | 830 | 26 | 45 | Developed | |

| Super high elongation (TRIP) | 780CR-type3 | 500 | 810 | 29 | 35 | Commercial production | |

| 980 | Conventional DP | JSC980Y | 690 | 1060 | 14 | 35 | Commercial production |

| High elongation DP | 980CR-type1 | 750 | 1030 | 15 | 45 | Commercial production | |

| High El- high λ | 980CR-type2 | 820 | 1020 | 16 | 60 | Developed | |

| Super high elongation (TRIP) | 980CR-type3 | 640 | 1030 | 23 | 30 | Commercial production | |

| 1180 | Conventional DP | JSC1180Y | 890 | 1230 | 10 | 30 | Commercial production |

| High elongation DP | 1180CR-type1 | 910 | 1260 | 12 | 40 | Commercial production | |

| High El- high λ | 1180CR-type2 | 1060 | 1215 | 15 | 55 | Developed | |

| Super high elongation (TRIP) | 1180CR-type3 | 950 | 1240 | 16 | 40 | Commercial production |

- *DP:

- Dual Phase steel

- **λ:

- Hole expanding ratio, index of stretch-flangability

- ***TRIP:

- TRansformation Induced Plasticity

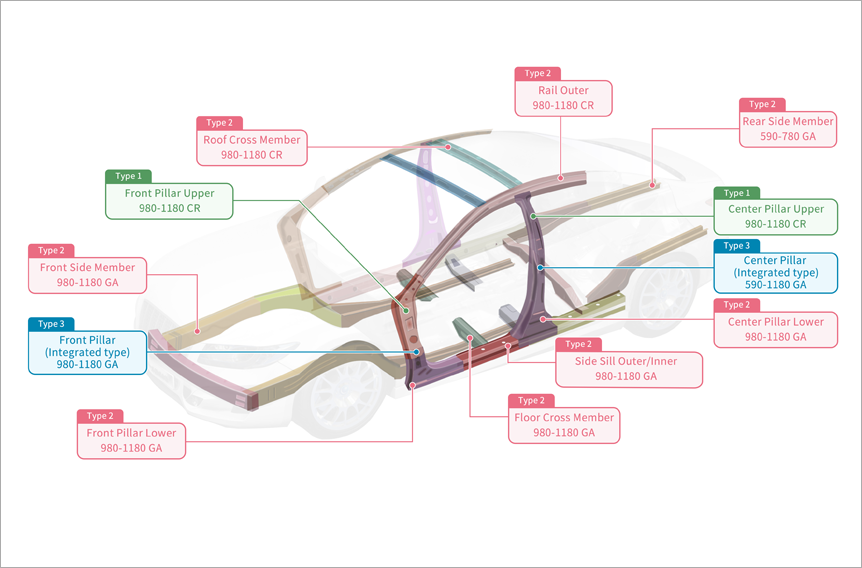

Applicable parts

Cold-rolled high-strength steel sheet series suitable for automotive structural parts due to excellent formability

JFE will provide the most suitable type of high-strength steel from the types of formability we feature based on the forming methods and shapes of parts. The highly formable, high-strength steel sheet series JEFORMA provides the stability of press-forming production and greatly expands the applications of high strength steel.

JEFORMA stands for JFE Excellent FORMAbility.