News Release

JFE Steel Corporation

JFE Steel and thyssenkrupp Steel Europe Launch High-tensile Steel Sheets

Capable of Cold Forming for Use in Automobile Frames

JFE Steel Corporation and thyssenkrupp Steel Europe (tkSE), Germany’s largest steel maker, announced today that they have jointly launched new 980- and 1180MPa-class high-strength steel sheets capable of cold forming for the production of automobile frame components. The products, which achieve higher yield strength and ductility, especially excellent local ductility, compared to conventional high-tensile steel sheets, will contribute to lighter-weight automobile body frames (“body in white”) and better crash safety performance. The new sheets also are expected to help raise productivity and lower manufacture costs by enabling customers to produce complicated-shape components using conventional cold forming (press & roll) rather than hot stamping.

Demands are growing for automotive designs that achieve energy savings, weight reduction for reduced CO2 emissions and enhanced crash safety performance. Steel that offers high strength for weight reduction, however, inevitably suffers from inferior formability, which is why it has been difficult to use high-strength steel to produce automotive components in complicated shapes.

To overcome this challenge, JFE and tkSE designed their steel sheets using a new composition and a microstructure that emphasizes local ductility. They also established a new heat-treatment method utilizing “quenching and partitioning, ” a metallurgical process in which the austenite phase, which forms at high temperature and contributes to ductility, is quenched from high temperature and then reheated to ensure stability at room temperature. Diverse intellectual properties from JFE and tkSE are incorporated in these new products and their manufacturing process.

The products will be supplied globally by JFE and tkSE for a wide range of applications in next-generation automobiles, including electric vehicles. The sheets will come in strength levels of 980 and 1180MPa and offer various types of coatings, including uncoated, galvannealed and galvanized. JFE and tkSE also will continue working on advanced products offering even higher strength levels.

Going forward, JFE and tkSE aim to contribute to a more sustainable world with high-tensile steel sheets that enhance passenger safety and lower vehicle weights for increased fuel efficiency and reduced CO2 emissions.

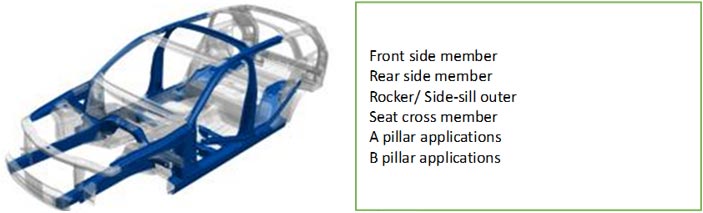

Applicable Components ©tkSE

thyssenkrupp Steel Europe

| Location | :Duisburg, Germany |

| CEO | :Bernhard Osburg |

| Sales | :Approximately 8.9 billion euros (FY2021) |

| Main Products | :Coated steel, cold-rolled steel, hot-rolled steel, etc. |

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 2,255 billion yen and consolidated crude steel output of 23.96 million tons in the fiscal year ended March 2021.

# # #