Cold-rolled steel sheets

Characteristics

- Wide range of product standards

- JFE produces cold rolled products to meet a wide range of product standards,

including JIS and other public standards, as well as internal JFE standards.

Products range from general use, including extra deep drawing quality and bake hardening sheets,

to high strength sheets and sheets for enameling and other special applications.

- JFE produces cold rolled products to meet a wide range of product standards,

- Superior workability

- JFE’s cold rolled products have excellent formability

and minimal deviation in mechanical properties thanks

to the company’s accumulated technical exper tise,

newly constructed and modernized facilities and innovative technologies,

and integrated quality control system extending from raw materials

to the final product.

- JFE’s cold rolled products have excellent formability

- Superior surface quality and dimensional accuracy

- Modern facilities,advanced operational technologies, strict inspection,

and integrated quality control ensure excellent surface quality. Dimensional

accuracy is guaranteed by an automatic thickness control system using advanced numerical models.

- Modern facilities,advanced operational technologies, strict inspection,

- Wide range of sizes

- The available size range includes thickness from 0.14mm

to 3.2 mm and width up to 1,850mm.

- The available size range includes thickness from 0.14mm

- Outstanding technical service

- To meet the requirements of diverse clients, JFE has

established a complete technical servicing system with advises

clients on questions ranging from material proper ties to

processing technologies.

- To meet the requirements of diverse clients, JFE has

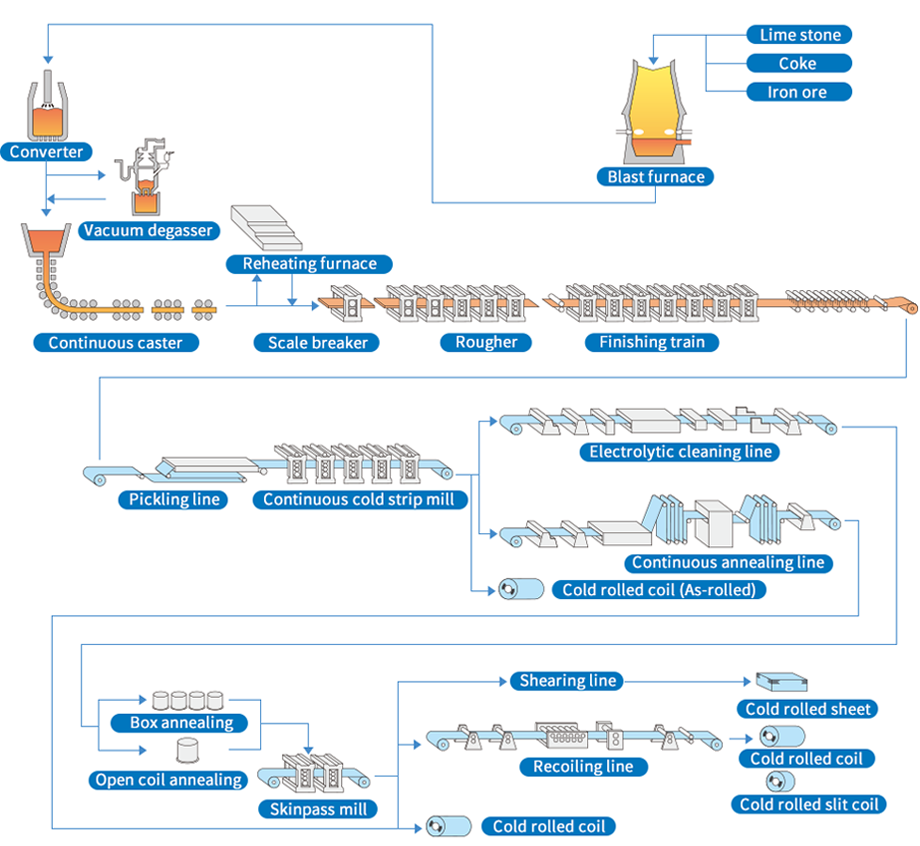

Manufacturing process

Upstream Process

Blast furnace

Converter

Continuous caster

Finishing train

The temperature and technologies of endless rolling determine the quality of cold-rolled steel products.

JFE produces high quality cold-rolled steel products using the latest equipment and technology, such as endless rolling, profile control, and Super -OLAC® H.

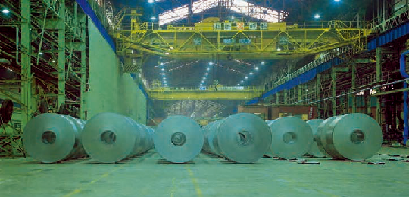

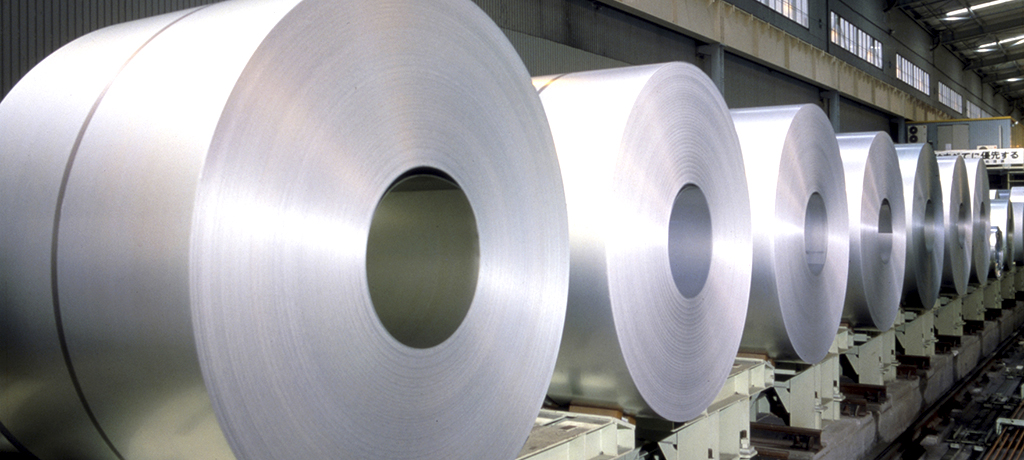

Cold rolling

The thickness accuracy of cold rolled products is determined by the cold rolling process.

Rolling force and strip tension are computer-controlled to minimize thickness deviations during rolling, based on measurements of the strip thickness at the entry and delivery sides of the mill.

Fully continuous cold strip mill

Annealing

The formability of products is determined by annealing.

Because cold rolling significantly increases material hardness, making forming difficult, annealing is performed to improve ductility by inducing a recrystallized structure in the steel. As the annealing process, coils are piled and covered by the box and annealed and this is called the batch annealing. The other is the continuous annealing process, in which coils are continuously treated. JFE uses two annealing technologies, depending on product requirements.

JFE is among the world’s leaders in process technology for the continuous annealing line (CAL), and has also used the CAL to develop a wide range of new products, from 1500N/mm2 high strength steel to non-aging extra deep drawing grade. JFE’s advanced CALs are highly computerized and feature automatic quality assurance equipment, such as an automatic surface inspection device which was developed by JFE.

Continuous annealing line

Finishing

After skinpass rolling, coils are processed at the recoiling line, where they are cut to produce product coils of the specified weight, or at the shearing line, where they are cut to sheets of the specified dimensions. Product thickness, width, shape, and surface quality are inspected, and mechanical properties are tested using specimens taken at the finishing line.

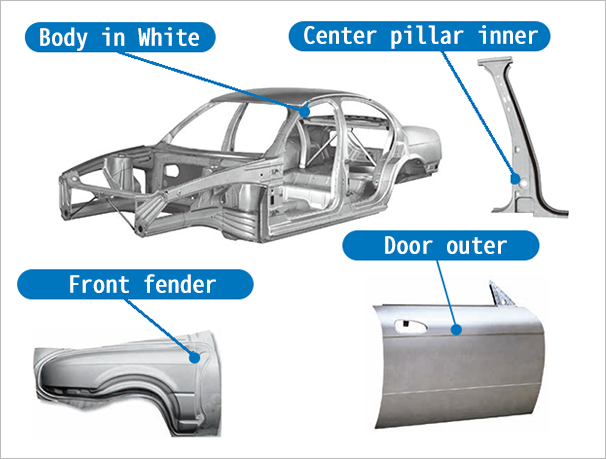

Application

Automobile

Drum

Electric appliances

Steel furniture

Cold rolled steel sheets offer a variety of outstanding properties, including easy formability and a smooth, clean surface, and are used in automobiles, appliances, furniture, and many other everyday items.

JFE Steel Corporation who holds ISO9001, QS-9000 and ISO14001 certifications, produces a full range of cold rolled products for these and other applications.

Because strict quality requirements are now applied to meet the needs of improved product functions, JFE has adopted an integrated quality control system.