| High Strength/ Machine Parts |

Machine Parts/ Bearings and Filters |

Magnetic Materials | Body warmers/Deoxidizers /Chemical reactants |

Welding rod coating/ Gas cutting/Aglicultual use |

Applications

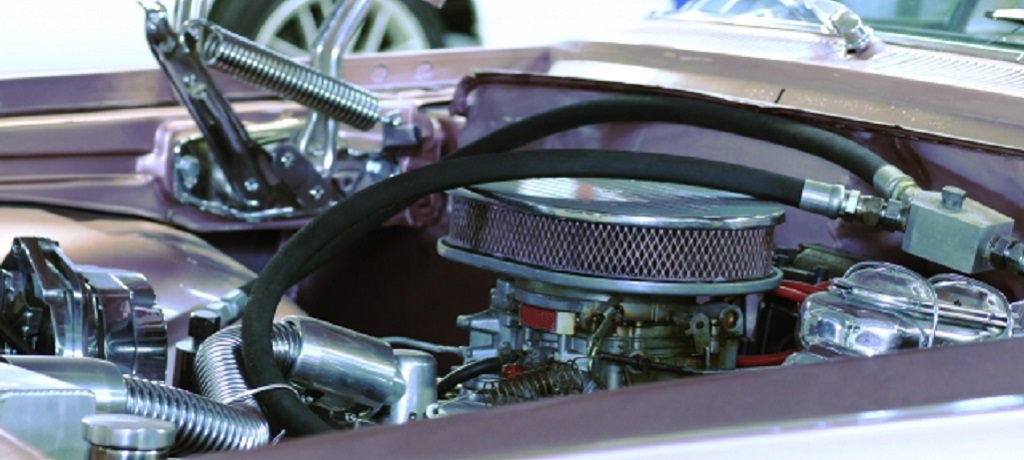

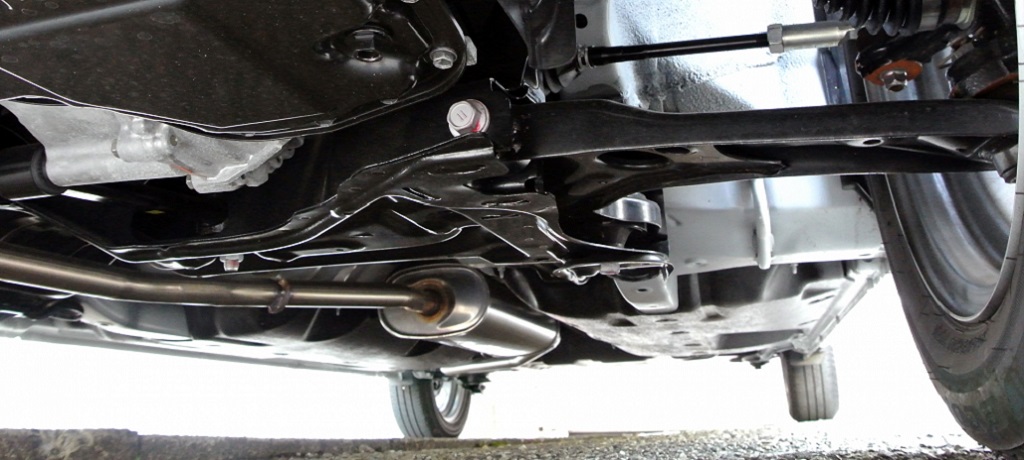

High Strength/Machine Parts - Ni-Free alloyed steel powder

Materials for high strength/ wear resistant parts, including Cr type, Ni type, and other composition systems. Fully alloyed steel powder is used with the Cr type and other composition systems; partially alloyed steel powder is used with the Ni type.

Ni-Free alloyed steel powder

■ Characteristic of JIP FM600

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

■Characteristic of JIP FM1000

|

||||||||||||||||||||||||||||||||||||||

■Characteristic of FM1000S

|

|||||||||||||||||||||||||||||||||||||||||||

■ Characteristic of JIP FM1300

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||