Products

What is iron powder?

Iron powder is an aggregate of iron particles with sizes of approximately 20-200 μ m. It is treated as a powder using the particle size distribution, apparent density, etc. as indexes. Its properties differ depending on the production method and history.

Commercial iron powders are classified in three types, reduced iron powder, atomized iron powder, and electrolytic iron powder, depending on the production method, and are used in various applications, taking advantage of their respective properties.

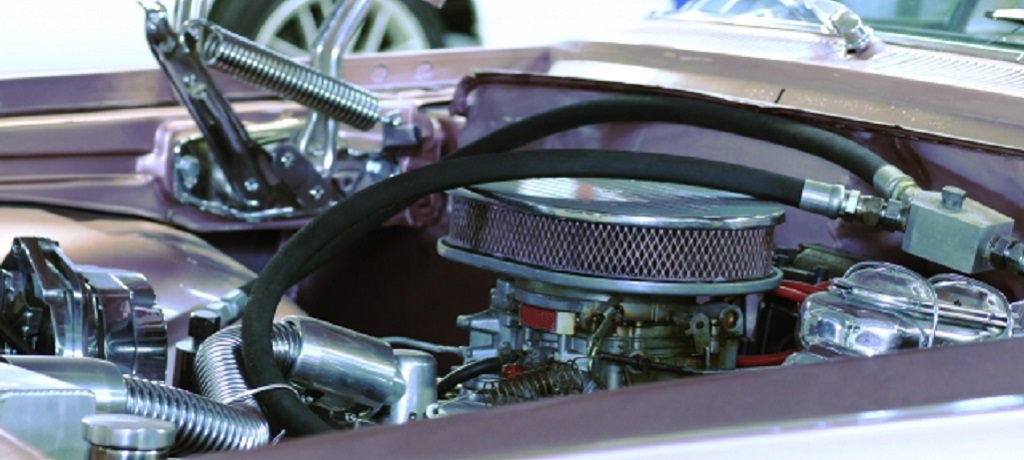

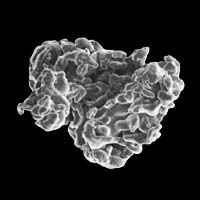

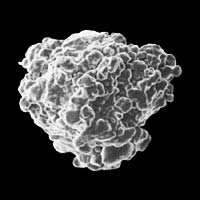

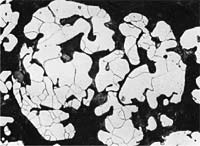

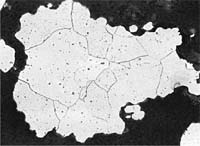

The following images show the appearance and cross-sectional microstructure of single particles of a representative reduced iron powder and atomized iron powder. Although there is little difference in the external appearance of the two types, the cross sections differ greatly.

Particles shapes of iron powders

|

|

|

| Reduced iron powder | Atomized iron powder |

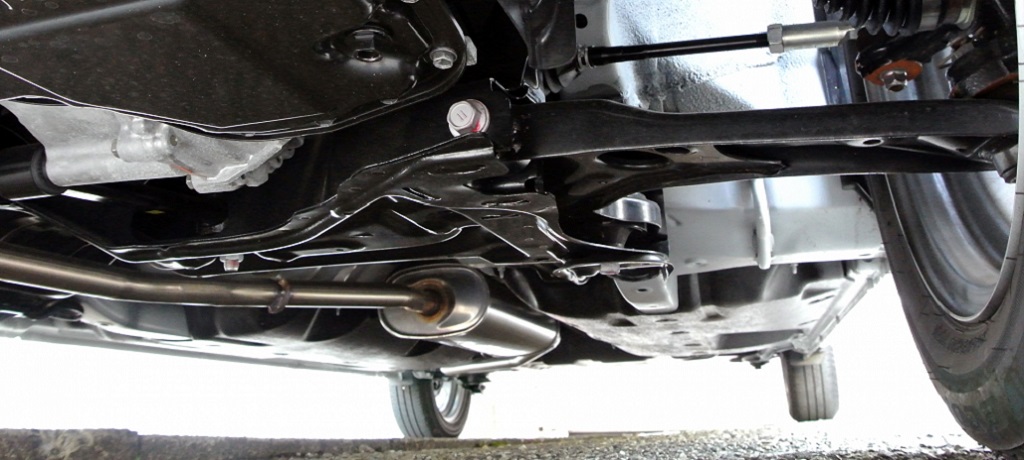

Cross-sectional microstructures of iron powders

|

|

|

| Reduced iron powder | Atomized iron powder |

Types of JIP Iron Powder

|

Pure iron powder |

Iron powder produced by reducing mill scale (iron oxide) with coke (carbon material), followed by heat treatment in a hydrogen atmosphere. Has a porous structure. |

||||||

|

Pure iron powder |

Iron powder produced by atomizing and cooling molten steel with high pressure water, followed by heat treatment in a hydrogen atmosphere. Not porous and has higher purity than reduced iron powder. |

||||||

Alloyed steel powder |

Fully alloyed steel powder |

Iron powder produced by atomizing alloyed molten steel. Has a uniform alloy composition in particles. |

||||||

Partialy alloyed steel powder |

Alloyed powder produced by partially alloying an alloyed powder, which is made to adhere around pure iron powder. Because the interior consists of soft pure iron powder, this type has high compressibility. |

|||||||

|

|

|

| ●Fully alloyed steel powder Distribution of alloying elements (Cr) in fully alloyed steel powder |

●Partialy alloyed steel powder Distribution of alloying elements (Ni) in partialy alloyed steel powder |

| Segregation-free powder (Clean Mix) |

Premixed powder consisting of a mixture of a pure iron powder or alloyed steel powder and additives. The powder can be compacted in this condition. |

JFE’s segregation-free treatment causes graphite powder or copper powder to adhere to the iron powder, preventing scattering of additives during handling. Contributes to a clean work environment, and enables production of sintered parts with minimal segregation of additives. |