News Release

JFE Steel Corporation

JFE Chemical Corporation

JFE Steel Launches Denjiro™ Insulation-coated Pure-iron Powder for Soft Magnetic Composites

—World’s only supplier of iron powders supporting all power-supply frequencies—

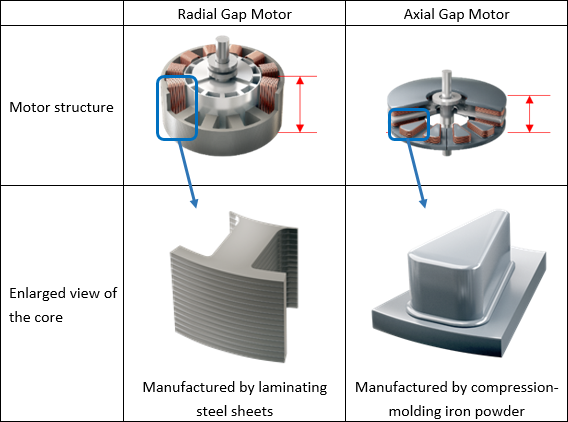

JFE Steel Corporation announced today its recent launch of Denjiro™ an insulation-coated pure iron powder for soft magnetic composites ideally suited to axial gap motors (Fig. 1). The launch, which expands JFE Steel’s broad lineup of soft magnetic materials, ranging from Electrical steel sheets to soft ferrite cores, solidifies the company’s status as the world’s only one-stop supplier of optimum solutions for all types of motors and other power-supply equipment.

Demands for extra-compact high-torque motors is growing in parallel with the popularization of EV. This includes the adoption of axial-gap motors, which are smaller than conventional radial gap motors thanks to their all-new structure (Fig. 1), and the expanding use of axial gap motors, particularly for vehicle-mounted applications.

A soft magnetic composite is an iron core made by applying an insulation coating to a soft magnetic1 iron powder and then compression-molding the powder. Compared to Electrical steel sheets, which are widely used for iron cores, soft magnetic composites achieve low loss at high operating frequencies and possess magnetic characteristics highly suited to complex-shape iron cores. The manufacturing yield of soft magnetic composites is favorable, allowing high-rpm motors to be produced at reduced cost. Furthermore, copper wire can be easily recovered when these motors are disposed, thereby contributing to recycling efforts.

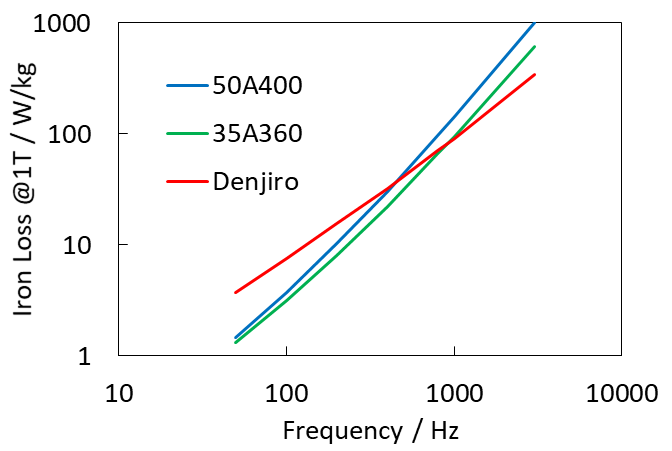

For example, a soft magnetic composite developed with Denjiro™ achieves less iron loss than both a 0.5 mm-thick Electrical steel sheet (50A400) in a frequency range exceeding 400 Hz and 0.35 mm-thick Electrical steel sheet (35A300) in a frequency range exceeding 800 Hz, demonstrating the suitability of soft magnetic composites for high-rpm motors including axial-gap models (Fig. 2).

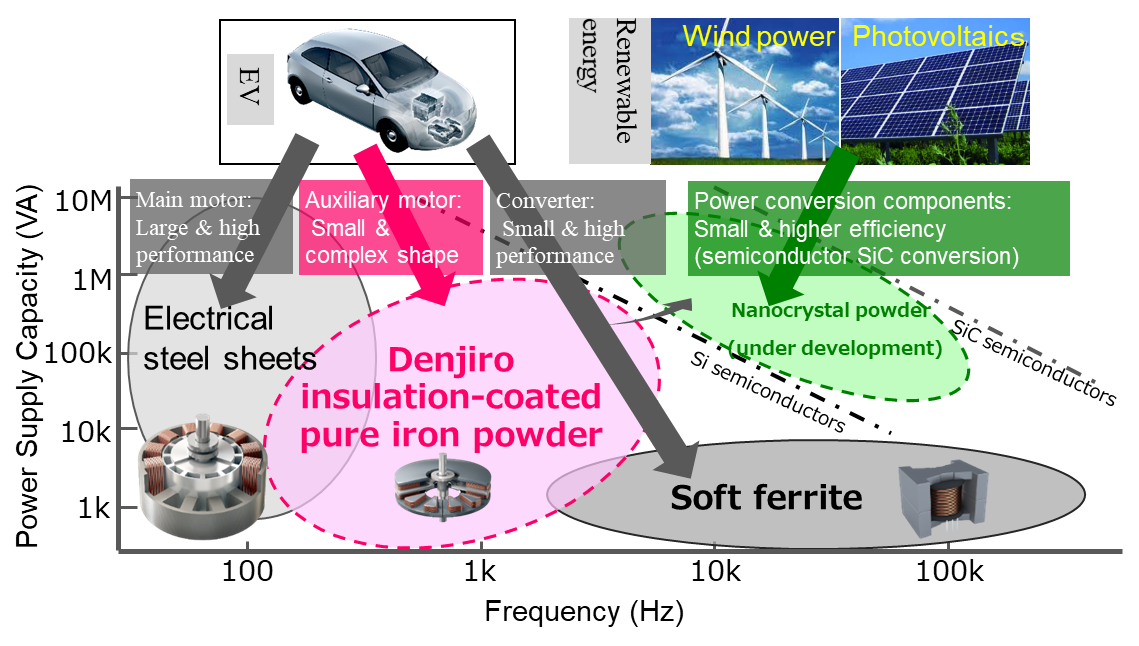

JFE Steel, with its newly commercialized Denjiro™ and existing Electrical steel sheets, now offers a comprehensive lineup of soft magnetic materials suited to nearly all currently applicable frequency ranges of power-supply equipment (Fig. 3).

JFE Steel’s subsidiary company JFE Chemical Corporation produces a soft ferrite core suited to the high-frequency ranges (several tens of kHz and higher) of inductors and electronic-device transformers. Soft ferrite cores are manufactured and sold through JFE Ferrite, a JFE Chemical company.

Meanwhile, the Functional Material Research Department of JFE Steel and the research division of JFE Chemical are working to reduce ferrite-core surface defects and improve the strength of soft magnetic materials by analyzing material characteristics to optimize internal structure and also by improving manufacturing processes.

In addition, JFE Steel is developing next-generation soft magnetic iron powders for the renewable energy field, such as nanocrystalline soft magnetic powders2 that contribute to the miniaturization and efficiency of power-conversion components used in wind power and photovoltaics.

Going forward, JFE Steel, the world’s only comprehensive supplier of soft magnetic materials, aims to use these materials to further develop and market excellent products offering improved quality, ultimately to contribute to a more sustainable world.

1 Soft magnetism is a property in which the magnetic force flexibly changes in response to changes in current. Also called soft magnetic materials, they are suited for use in the iron cores of motors and transformers. Conversely, hard magnetic materials are suited for use as permanent magnets, etc.

2 Nanocrystalline soft magnetic powder is an iron powder for which the structure is controlled on a nano level using innovative materials and manufacturing processes. A minute nanocrystalline structure exhibiting excellent magnetic characteristics is formed through a unique heat-treatment process. In the high frequency range, the iron loss of magnetic components manufactured with nanocrystalline soft magnetic powder is extremely low and thus contributes to the efficiency of EV and the power conversion efficiency of renewable energies.

Fig. 1: Types of Motors

Fig. 2: Iron Losses of Soft magnetic composite core “Denjiro” and Electrical steel sheet cores

Fig. 3: Soft Magnetic Materials of JFE Group

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 2,255 billion yen and consolidated crude steel output of 23.96 million tons in the fiscal year ended March 2021.

# # #