Iron Powder & Magnetic Materials

Taking advantage of iron and steel production technologies, the Iron Powder & Magnetic Materials Research Dept. is engaged mainly in the development of new iron powder products which contribute to make sintered parts more sophisticated.

Segregation-Free Powders

A segregation-free premixed powder, in which graphite, copper, and other materials are bonded on the surface of iron powder particles, enables production of sintered parts with reduced fluctuations in dimensions and properties. Powder engineering methods, such as die filling simulation, etc. are applied for designing the segregation-free powders.

Particle velocity distribution derived from a computer simulation (SAFIRE)

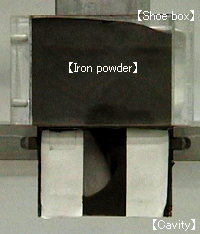

Powder filling visualization device

A green compact with a complex geometry

Iron Powder Production Technologies

Based on experimental and numerical simulations of the actual production process, JFE Steel has developed new production technologies to improve not only the quality but also the productivity of the iron powder products.

Atomizing equipment for experimental production of various kinds of alloyed steel powders

Reduction furnace for powder annealing experiments

Alloyed Steel Powders

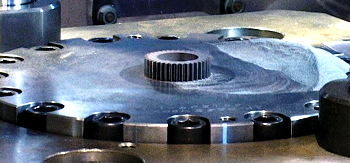

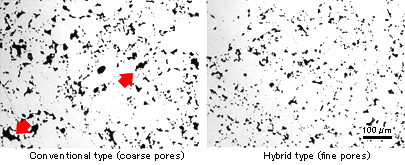

JFE Steel has developed a number of alloyed steel powders based on alloying and microstructure control technologies. The hybrid-type Mo alloyed steel powder makes the pore structure of the sintered steels extremely fine. This will contribute to reduce the cost for producing high strength sintered parts.

Pore structure in sintered compacts of conventional-type and hybrid-type Mo alloyed steel powder