Automotive Sheet Products

Making full use of precipitate, transformation structure, and texture control technologies, the Automotive Sheet Products Research Department is developing high strength steel sheets suitable for weight reduction in automotive parts.

Stretch-Flangeability Improvement Technology(Suspension Parts)

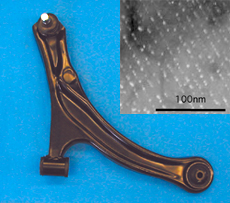

Suspension arm formed using 780MPa class NANO-HITEN and TEM image of nano-sized precipitates

Excellent stretch-flangeability is required in steel sheets for suspension parts. JFE Steel has developed a new steel sheet with a uniform microstructure and high stretch-flangeability by fine dispersion of nano-sized precipitates.

Stretch-Formability Improvement Technology(Panels)

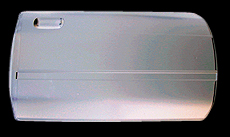

440MPa class UNI-HITEN developed for door panels

Deep-drawability and stretch-formability are the essential properties in steel sheets applied for automotive panels. For the closure panels as shown below, JFE has developed UNI-HITEN with improved stretch-formability by controlling the dispersion of hard second phase and matrix texture.

Crashworthiness Improvement Technology (Frame and Structural Parts)

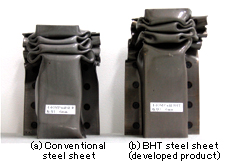

Comparison of appearance of column-shaped parts after drop weight test

A high impact absorbing property (crashworthiness) is necessary in members, pillars, and other frame and structural parts of automobiles. BHT (bake hardenable) steel sheets are a type of steel sheet in which solid solution nitrogen is used to realize a property of substantially increased tensile strength after paint baking process. BHT sheets have the distinctive feature of an enhanced impact absorbing property in easy-to-form parts.

Technology for Improved Formability in High Carbon Steel(Drive Train Parts)

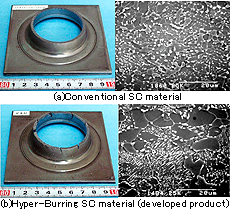

Comparison of appearance after flange forming and microstructure

Hyper-Burring SC is a high carbon steel sheet with a uniform microstructure obtained by controlled cooling after hot rolling, resulting in improved elongation and stretch-flangeability. This product enables users to reduce production cost of drive train parts by converting the forging process, etc. to press forming.