Steelmaking

With the aid of various experimental and numerical simulation techniques, etc. the steelmaking process supplies the basic material for high quality, high function steel products. The Steelmaking Research Dept. is also developing high efficiency, environment-friendly steelmaking processes.

Technology for Promotion of High Temperature Refining Reaction/Solidification Control

Molten steel casting experiment using small-scale continuous casting machine

Using simulators for the refining and solidification processes and other techniques, the Steelmaking Research Dept. performs small-scale experiments using hot metal (molten pig iron) and molten steel to reproduce the high temperature phenomena in actual operation, and is also developing innovative new steelmaking processes.

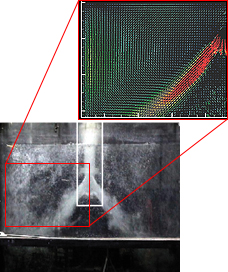

Visualization/Estimation Techniques for Physical Phenomena in Actual Equipment

Experiment reproducing flows in continuous casting mold using water model and results of measurement of flow velocity by image processing

Flows in refining furnaces and the continuous casting mold, etc. are simulated by cold model experiments based on the Law of Similarity, making it possible to estimate phenomena and supporting process improvement/development.

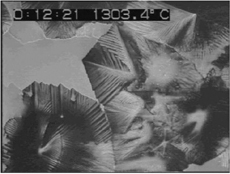

Evaluation of Fundamental Phenomena in Reaction/Solidification Process

Results of direct observation of mold flux solidification phenomenon by high temperature laser microscope

In elucidating the fundamental events of high temperature reaction/solidification phenomena, which are the basis for process development, the Steelmaking Research Dept. makes full use of state-of-the-art experiment and evaluation devices.

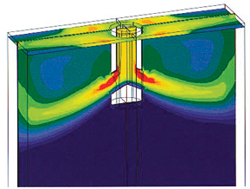

Numerical Simulation Analysis Technology for Fluids

Example of analysis of flow velocity of supersonic oxygen jet stream from the converter lance nozzle

To optimize operating conditions and predict the effect of introducing new processes, simulations using numerical calculations are performed for the behavior of the oxygen jet stream in the converter, flow of molten steel in the continuous casting mold, etc.

Example of analysis of flow of molten steel in continuous casting mold