Tubular Products & Casting

Development of advanced products and technologies which respond to environmental needs and realize higher functions in oil country tubular goods (OCTG), linepipe, steel tubes for automotive applications, and other products makes it possible to respond to customer requirements in a timely manner.

OCTG/Linepipe & Corrosivity Evaluation Technologies

Drilling environments for oil and natural gas have become deeper and more severe in recent years, and extremely strict requirements are now placed on materials. As a result, the need for tubular products with high corrosion resistance is increasing by the year. To meet these requirements, the Tubular Products & Casting Research Department is developing new products in the field of stainless steel OCTG and linepipe, contributing to the development of oil and natural gas resources worldwide.

Sea bottom oil field using 13Cr OCTG

Laying 12Cr linepipe

Steel Tubes for Automotive Applications & Secondary Formability Evaluation Technologies

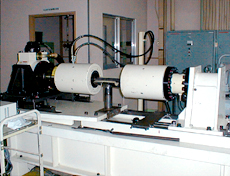

Large-scale torsion fatigue testing machine

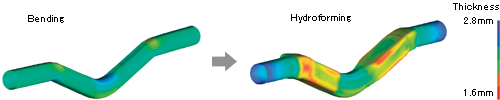

Together with the development of steel tubes for automotive applications such as the HISTORY tubes and high strength ERW tubes, which feature outstanding formability and fatigue resistance characteristics, the Tubular Products & Casting Research Dept. is also developing forming technologies for high efficiency production of actual parts from these tubes, as well as numerical analysis technologies.

FEM simulation of tube bending ⇒ hydroforming process

High Reliability Process Technologies for Steel Pipe

JFE Steel is responding to customers·trust through the development of leading-edge process technologies such as high reliability welding technologies for electric resistance welded (ERW) steel pipes, high dimensional accuracy forming technologies for seamless steel pipes, material quality controls using the pipemaking processes, and others.

Seamless steel pipe piercing experiment (for OCTG/linepipe)

ERW welding experiment

Cast Rolls & Design/Manufacturing Technologies

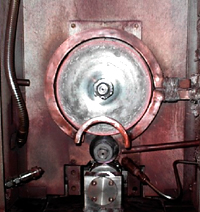

Hot wear simulator

Accompanying the trend toward higher grade/higher quality in rolled steel products, the properties and quality required in rolls for hot rolling have become strict. JFE Steel has developed centrifugally-cast high speed steel (HSS) rolls with excellent wear resistance and surface deterioration resistance, thereby contributing to the progress in rolling technologies.

Centrifugally-cast HSS roll