Electrical Steel

The Electrical Steel Research Department conducts research and development of high function electrical steel sheets which contribute to reducing CO2 emissions and saving energy through realizing high performance transformer and motors.

Grain-Oriented Electrical Steel Material Technology

Growth of crystal grains with aligned orientations (colored blue)

Grain-oriented (GO) electrical steel sheets for transformer cores are manufactured using sophisticated technologies and have been called “art work of steel.” Using JFE’s leading-edge technology, the company has developed the world’s highest performance GO electrical steel sheets, which feature greatly reduced iron loss and acoustic noise in transformers.

Magnetic domain structure of inovative low-iron-loss GO steel sheet(left) and pole transformer using

the developed material (right)

Non-Oriented Electrical Steel Material Technology

Motor cores using NO steel sheets

Reactor of a hybrid car using Super Core

Non-oriented (NO) electrical steel sheets, which are used in motors for home and industrial electrical appliances and pure and hybrid electrical vehicles, represent the crystallization of advanced material technologies. JFE Steel has developed the world's leading product lineup, which includes highest-grade low iron loss material, high magnetic flux density material, and high functionality coatings, as well as unique 6.5% Si electrical steel called SuperCore.

Electrical Steel Utilization Technology

Distribution of magnetic flux density and iron loss in a motor core

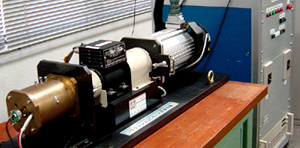

Electrical Steel Research Dept. is also developing material utilizaition technologies which set new standards for performance in transformers, motors, and other apparatuses. These activities, with effective use of magnetic field analysis and newest magnetic measurement techniques, aims at contributing to material development which respond to user's needs and extend company's proposal-oriented business.

Motor properties test equipment