Analysis and Characterization

Analysis & Characterization Research Department is carrying out researches to promote product development and process designing by fully utilizing physical/chemical analytical techniques both inside and outside the company. State-of -art analytical techniques are applied to reveal the microstructures which govern the mechanical / surface properties of steel products.

Structural Analysis

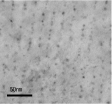

Advanced transmission electron microscope (TEM)

Analysis of nano-precipitates in steel by TEM

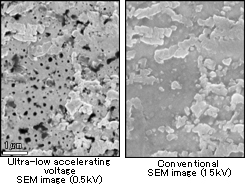

Taking advantage of advanced physical/chemical analytical techniques, the Analysis & Characterization Research Dept is promoting material development and process optimization based on the precise characterization of the microstructures and surfaces which control various properties of high-quality steels.

Analysis of surface oxides on steel (images show same field of view)

Trace Analysis-Speciation Technology

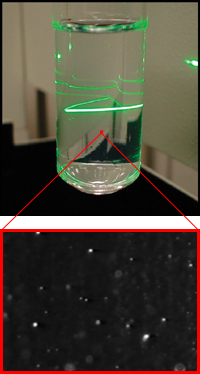

The Analysis & Characterization Research Department is engaged in the development of a wide range of analytical techniques, beginning with analysis of inclusions/precipitates, which have a large effect on the properties of steel products, extending from analysis of trace elements in various materials, including iron and steel, raw materials, and environmental specimens, etc., to quantitative analysis by chemical form. This research supports new product development and control for high production quality manufacturing.

Analysis of particle size distribution of fine precipitates in steel by dynamic light scattering method

Process Analysis

The Analysis & Characterization Research Department is contributing to the production of high quality steels, with quality built in as part of the manufacturing process, and to stable production of products through high speed, high sensitivity analytical techniques using laser, etc. and on-line techniques using X-ray, infrared, and other methods.

Rapid analysis technique using LA-ICP analysis