Bar & Wire

The Bar & Wire Research Dept. is creating new materials as automotive specialty steel products which anticipate the customer’s needs from a standpoint which includes the customer’s forging and heat treatment processes.

Microstructure Control Technology for Automotive Steel Bars

To realize compact size, weight reduction, and high performance in automobile parts, the Bar & Wire Research Dept. is developing new products utilizing diverse microstructure control technologies such as ultra-refinement of γ grains in steel products (Fine γ).

Crankshaft

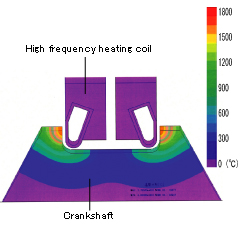

Multi-type high frequency heat treatment equipment for γ grain refining

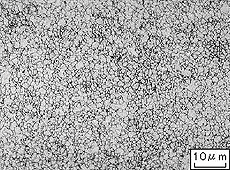

Grains in Fine γ (grain size: 2-3μm)

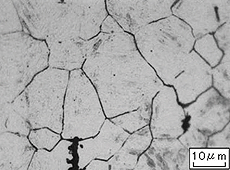

Grains in general carbon steel (S53C) (grain size: 20μm)

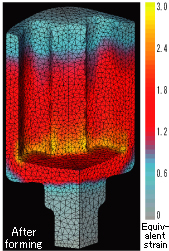

CAE Considering Customer’s Process

Specialty steels are used in components which are formed/heat-treated by the customer. The Bar & Wire Research Dept. develops the optimum steel product for the customer’s forming/heat treatment process, and also proposes the optimum forming and heat treatment processes.

Example of analysis of temperature distribution during high frequency hardening of crankshaft pin part

Example of analysis of strain distribution during forging of constant velocity joint

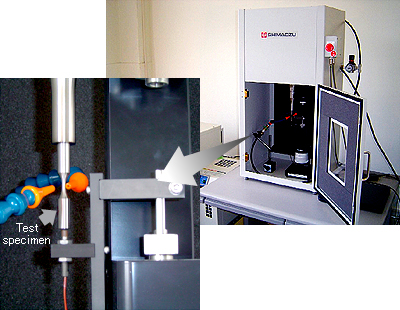

Development of Bearing Steels by Advanced Evaluation

Bearings are important components which are used in rotating parts of all types of machinery, including automobiles. Using the more advannced evaluation technique, JFE Steel is developing bearing steels with superior product quality and high performance.

Evaluation of fatigue life of bearing steel using ultrasonic fatigue testing machine