Joining & Strength

The Joining & Strength Research Department develops original technologies and products to ensure that customers can use JFE’s outstanding steel products in welding applications with high efficiency and complete confidence.

Joining Technology for Thin Steel

TThe Joining & Strength Research Dept. is developing joining technologies of high strength steel sheets for automotive use. This Research Dept. has the advanced facilities such as YAG laser and friction stir spot welder as well as widely-used spot and arc welders, and is grappling with the development of original welding technologies. These technologies are contributing to materials proposals/VA proposals to customers.

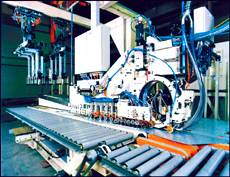

Laser welding facility for production of tailor-welded blanks(TWB)

Ultra-low spatter CO2 arc welding technology(J-STAR welding)

Joining Technology for Heavy Steels

JFE Steel supports customers with a variety of innovative/unique joining and analytical technologies for steel materials (plates, pipes, stainless steel) in all fields, including automobiles, shipbuilding, steel pipe, social infrastructure, etc., from thin to heavy-gauge materials, with various kinds of welding technologies ranging from laser welding of a small heat input to electroslag welding of an extra- large one.

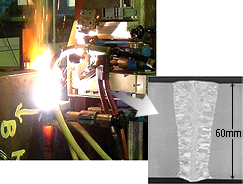

Large heat input 1-pass electrogas arc welding of shipbuilding plates (plate thickness: 60mm, welding heat input: 45kJ/mm)

Example of analysis of residual stress in circumferential weld of small diameter pipe

Safety Assessment/Analysis Techniques

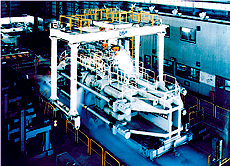

80MN structural tensile testing machine

The Joining & Strength Dept. also conducts research on advanced assessment/analysis techniques for fatigue, fracture, and strength in order to enhance the safety and life cycle value of steel structures. These techniques are contributing to steel material development and proposals regarding the use of steel materials by customers.