Stainless Steel

Ferritic Stainless Steels with Only 1 and No. 1 Properties

Pursuing the potential of ferritic stainless steels to their ultimate level, JFE Steel's Stainless Steel Research Department is developing stainless steels with the world's highest level properties, as well as high efficiency production processes.

Heat Resistance Technology

Automobile exhaust manifold made from JFE-MH1

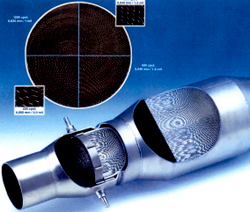

Responding to increasing temperature in automobile engines, which are required to solve environmental and energy problems, and demand for higher heat resistance in motorcycle disk brakes, the Stainless Steel Research Dept. is contributing to the realization of these needs through the development of exhaust manifold materials with excellent heat resistance and oxidation resistance by precipitate control technology, automobile catalyst substrate materials, and heat resistant disk brake materials, etc.

Automobile catalyst carrier made from JFE20-5USR

High Corrosion Resistance and its Evaluation Technology

A pot of JFE443CT

JFE Steel has developed high corrosion resistance ferritc stainless steels by manufacturing techniques for extra low carbon and high Cr steels. Ni/Mo-free JFE443CT has the corrosion resistance in the same level as SUS304 and JFE30-2 is suitable for the roofs of buildings in coastal area. JFE Steel proposes the optimum stainless steel products for customers with high level corrosion evaluation techniques based on the results of field exposure or accelerated corrosion tests.

Example of application of JFE30-2 to roof (Kansai International Airport)

High Formability Technology

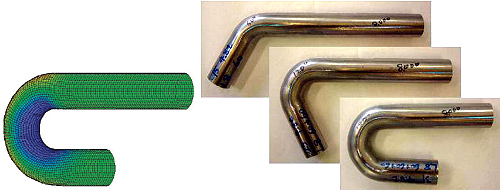

The Stainless Steel Research Dept. is contributing to development of products and solution of forming problems for its customers by developing SUS430 and various types of ferritic stainless steels with high elongation and r-values making full use of high purification/hot rolling technology. JFE Steel proposes the optimum forming method along with product configuration utilizing CAE technology that incorporates material properties with high accuracy.

Forming of automobile exhaust gas system part

High Productivity Technology

Example of production of SUS430 by tandem mill-CAL process (frame for liquid crystal display)

To supply stainless steels with the highest cost performance to customers, JFE Steel has developed a unique smelting reduction steel making process using Cr ore and has also developed a high efficiency process using ordinary carbon steel production line and a new process which makes it possible to omit annealing of hot coils.