Plate & Shapes

Steel products must be strong and tough, have good weldability, and be capable of enduring severe service conditions from cryogenic to extremely high temperatures. The Plate & Shapes Research Department is developing the steel products which will support tomorrow’s social infrastructure through microstructure control using alloy design and advanced processes.

Microstructure Control Technology for HAZ in Large Heat Input Welding

To realize high efficiency welding in shipbuilding and construction, the Plate & Shapes Research Dept. is developing steel plates with high strength/toughness and weldability applying the microstructure refining technology, which includes inclusion control.

ĚDispersion of fine particles suppresses grain growth.

ĚDispersion of transformation nuclei in steel promotes formation of intragranular ferrite.

Refinement of microstructure by control of inclusions/precipitate dispersion

Refinement of microstructure by control of inclusions/precipitate dispersionTechnology for Improving Deformation Performance for Earthquake Resistance

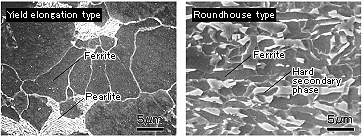

Considering seismic performance, steel products with high strength and high deformation performance are required in the fields such as building construction and UOE pipes. JFE Steel meets these requirements using a technology which enables microstructure control with hard and soft phase.

Microstructure control by optimization of microalloys and rolling process (SEM photograph)

Strength & Toughness Technology for High Performance Steel

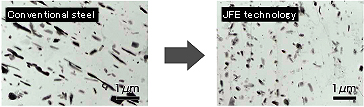

To realize strength and toughness, which are fundamental requirements in all fields, the Plate & Shapes Research Dept. is developing steels which can meet diverse needs by combining grain refinement control which considers the crystal orientation and carbide refinement/dispersion by rapid heating/tempering, etc.

Refinement control of microstructure by optimization of microalloys and controlled rolling(Optical microscope photograph using stain etching technique)

Control of carbide refinement/dispersion by rapid heating/tempering(TEM photograph by extraction replica method)

xample of on-line quenching/tempering process for steel plates