Ironmaking and Environmental Process

Looking to the future, Ironmaking & Environmental Process Research Department is involved in research and development aimed at realizing new ironmaking processes which are environment-friendly and conserve resources.

Blast Furnace

Advanced numerical analysis of blast furnace phenomena

Technologies to reduce a reducing agent rate (RAR) and increase a productivity of blast furnace have been developed Through research on high accuracy burden distribution control, furnace bottom permeability control, and advanced numerical analysis. The company aims also include the construction of a new blast furnace process which minimizes CO2 emissions by utilizing innovative blast furnace raw materials such as new iron sources and high reactivity coke, etc.

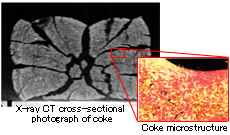

Coal & Coke

Based on a structural analysis of coal, which is the raw material for coke, down to the molecular level and research on the mechanism of the carbonization reaction in cokemaking, the Ironmaking and Environmental Process Research Dept. aims at establishment of a high efficiency coke production process which is highly effective in using a wider range of coal resources.

Raw Materials & Sintering

Through research on the sintering reaction involving iron ore, permeability analysis of the sintering bed, and other factors, JFE Steel aims to expand the use range of low grade ores, and to improve productivity and achieve high quality in the sinter product. The company is also engaged in the development of new processes such as the limestone/coke coating granulation process with the aim of reducing CO2 emissions and improving the structure of the sinter products.

New Ironmaking, Environmental, and Recycling Technologies

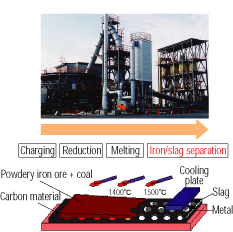

Hi-QIP process

esearch topics in this field include an innovative ironmaking process (Hi-QIP) for production of iron pebble from powdery iron ore and coal and advanced use of wastes such as waste plastics, which can contribute to protection of the global environment by reducing CO2 emissions and minimizing the amount of waste discharged from the steel works.

Recycling of waste plastics as blast furnace feed