Application technology

- Mechanical properties evaluation

- Body rigidity and durability evaluation

- Crashworthiness evaluation

- Performance evaluation of outer panels

- Analysis of body-structures and their performance

- Press-forming simulation

- New forming technology

- Joining techniques for steel steets

- Corrosion performance evaluation techniques

Corrosion Performance Evaluation Techniques

Background

Corrosion analysis in JFE Steel

Since the 1990's, we have been conducting original analysis on corrosion conditions in the de-icing salt areas mainly in North America.

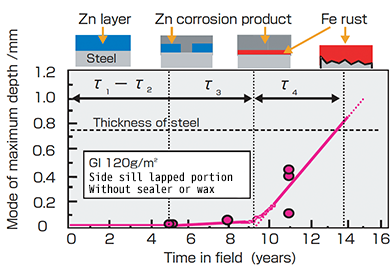

Example of corrosion analysis

Results of actual vehicle analysis in North America (Detroit)

Anti-corrosion effect by Zn coating Approx. 13g/m2・year

Corrosion rate of steel Approx. 0.15mm/year

Corrosion environment in the actual vehicle and testing condition

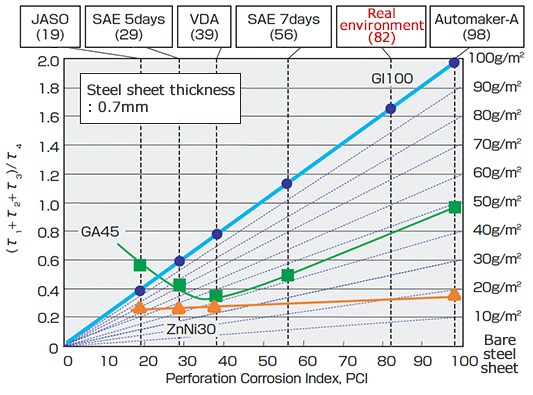

Perforation corrosion index

PCI(Perforation Corrosion Index)

PCI=V(Steel)/V(Coating)

V(Steel)=Thickness of steel/τ₄

V(Coating)=Thickness of Zn coating/

(τ₁+τ₂+τ₃)

By utilizing PCI, we can quantitatively understand the relationship between various corrosion test environments and actual automotive corrosion environments.

⇒Optimization of the corrosion test method

Based on the corrosion test results, the actual corrosion performance of zinc and zinc alloy coated steel sheets can be estimated.

⇒Appropriate material selection

Although the corrosion performance of automotive steel sheets is evaluated by various corrosion tests, corrosion behavior varies depending on the use environment; therefore, the optimization of the corrosion test method is important. JFE Steel has studied corrosion behavior quantitatively with detailed data in actual corrosion environments in various regions. By doing so, we propose the appropriate corrosion test method and material selection, contributing to anti-corrosion designs of automobile bodies.