JFE432LTM

Stainless steel for cold end (low temperature) use

<Composition> 18Cr - 0.5Mo - Ti - ultra-low (C, N) (SUS436J1L)

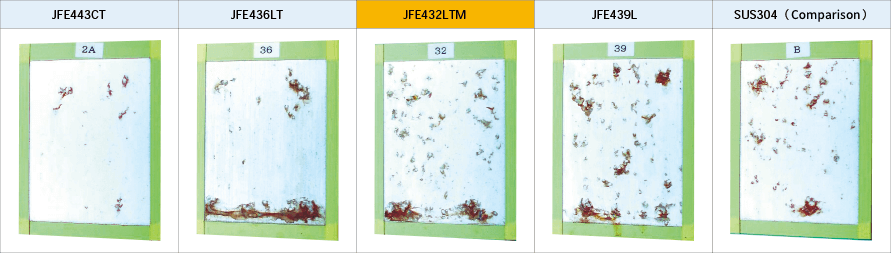

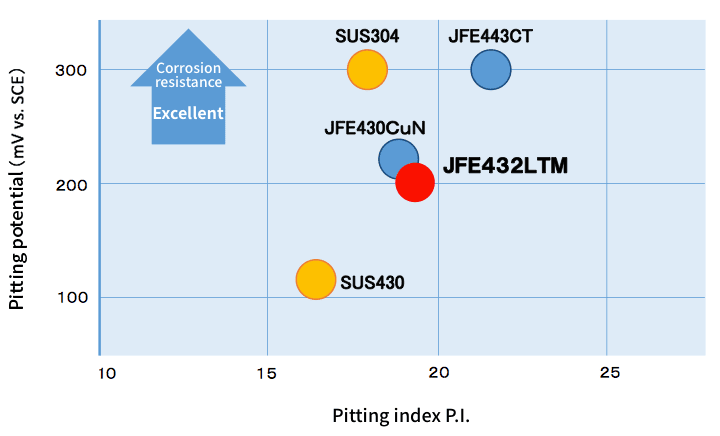

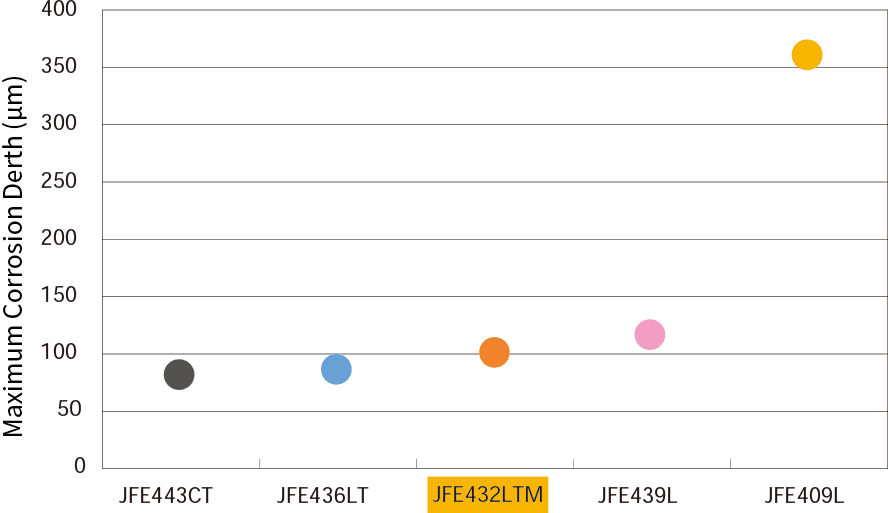

comparison of corrosion resistance

Weldability

Corrosion resistance

- This ferritic stainless steel (ultra-low C, N, added Ti), manufactured using advanced smelting technology, combines excellent formability and corrosion resistance.

- Made using an optimized production process of tandem cold rolling and CAL annealing and pickling, resulting in exception cost performance.

Applications

- Stainless steel parts/materials for automobiles

- Mufflers, muffler cutters, exhaust gas pipes, etc.

Chemical composition

| Steel grade | Correspoding Standards | Composition (weight %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Cu | Mo | Ti | N | Other | |||

| JFE432LTM | SUS436J1L AISI439 |

Std. | ≦ 0.025 | ≦ 0.75 | ≦ 1.00 | 17.00 - 19.00 | - | 0.40 - 0.80 | 8×(C+N) - 0.80 | ≦ 0.015 | |

| Typical values | 0.008 | 0.12 | 0.18 | 17.45 | - | 0.54 | 0.27 | 0.008 | |||

Physical properties

| Steel grade | Physical properties | |||

|---|---|---|---|---|

| Density (g/cm³) | Young’s modulus (×10³MPa) | Thermal expansion coefficient 0-650°C (×10-6/℃) | Thermal conductivity 100° (W/m・℃) | |

| JFE432LTM | 7.73 | 206 | 11.6 | 24.0 |

| SUS430 (comparison) | 7.70 | 200 | 11.9 | 26.1 |

| SUS304 (comparison) | 7.93 | 193 | 18.7 | 16.2 |

| Common steel (comparison) | 7.87 | 206 | 15.0 | 57.7 |

Mechanical properties

| Steel grade | Mechanical properties (top: std. value, bottom: typical value for L direction), thickness: 0.8 mm | |||||

|---|---|---|---|---|---|---|

| 0.2%Yield strength(MPa) | Tensile strength(MPa) | Elongation (%) | Hardness Hv | n value | Average r value | |

| JFE432LTM | ≧ 205 | ≧ 390 | ≧ 25 | ≦ 200 | 0.25 | 1.4 |

| 250 | 461 | 31 | 144 | |||

| SUS430 (comparison) | 318 | 488 | 29 | 155 | 0.20 | 1.0 |

| SUS304 (comparison) | 279 | 652 | 57 | 167 | 0.34 | 1.0 |

| Common steel (comparison) | 185 | 317 | 40 | 90 | 0.22 | 1.5 |

Corrosion resistance

1. Inner Corrosion Resistance

2. Outer Corrosion Resistance