Manufacturing Process

A wide range of steel pipe products are manufactured using a streamlined system featuring highly advanced technology and equipment.

Chita Works

West Japan Works(Fukuyama)

East Japan Works(Keihin)

East Japan Works(Chiba)

As an international steel making pioneer, JFE Steel boasts two integrated steelworks-East Japan Works, extending over two locations in eastern Japan (Chiba and Keihin), and West Japan Works, over two locations in western Japan (Kurashiki and Fukuyama) - as well as a specialized pipe and tube production mill in central Japan (Chita Works). At these facilities JFE Steel manufactures and ships almost every kind of steel product. Our diverse range of steel pipe products, manufactured using the most advanced technology and state-of-the-art facilities to stringent quality control standards, are proving their capabilities in energy projects across the globe, as well as a broad variety of other applications in the automotive, chemical, industrial machinery, construction and civil engineering, and other industries.

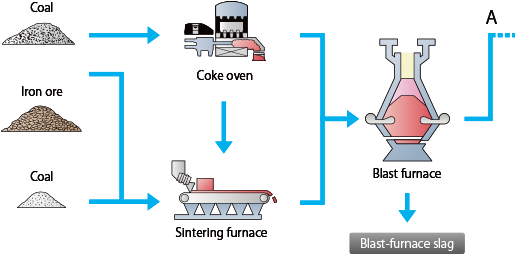

Ironmaking

Steelmaking

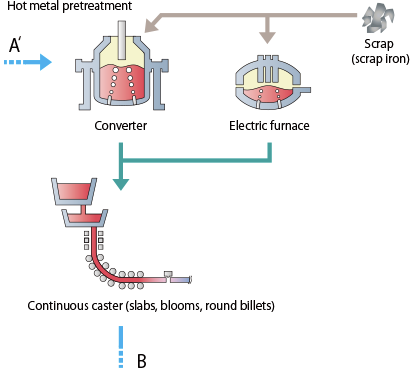

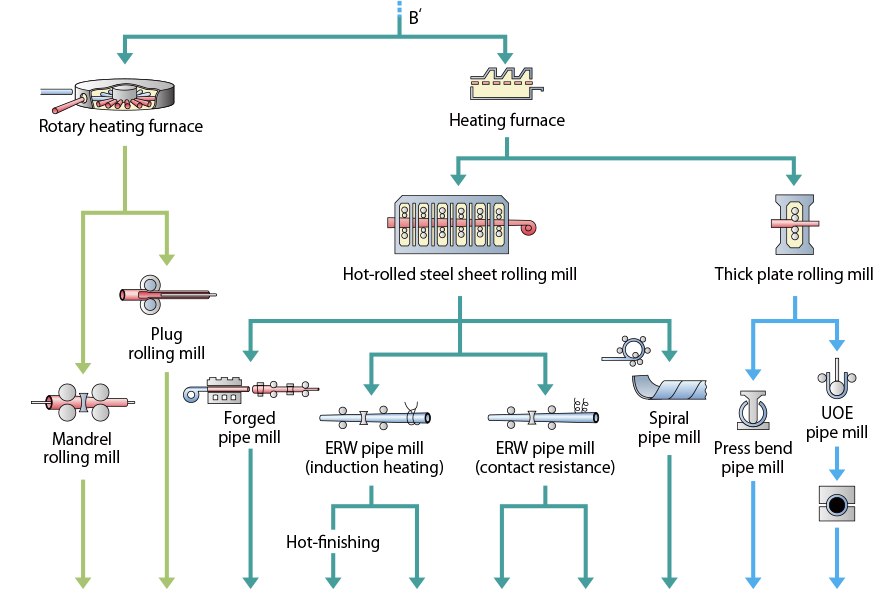

Rolling and products

Small-diameter seamless steel pipe

This small-diameter seamless steel pipe is made by piercing round billets of heated steel and then rolling them in a mandrel mill.

Medium-diameter seamless steel pipe

This medium-diameter seamless steel pipe is made by piercing round billets of heated steel and then rolling them in a plug mill.

Forged steel pipe

This steel pipe is made by forming a hoop of steel, heated to a high temperature, into a cylindrical shape and then forcefully welding (forge welding) the two edges together.

Small-diameter hot-finished

ERW steel pipe (4”)

This is high-performance steel pipe (HISTORY steel pipe) equipped with high strength and excellent formability by limiting the addition of alloy elements.

Small-diameter ERW steel pipe (6”)

Small-diameter steel pipe can be manufactured with an outside diameter of 28.6 mm to 168.3 mm, enabling supply of optimum steel pipe for specific applications.

Medium-diameter ERW steel pipe

(Chita Works)

The Chita Works manufactures ERW steel pipe up to 660.4 mm in outside diameter and it has also produce the world’s largest ERW steel pipe for construction, of 700 mm outside diameter.

Medium-diameter ERW steel pipe

(East Japan Works)

This steel is made by forming hot rolled coil into a tubular shape and then welding with a high-frequency resistance welding (HFW) process. The East Japan Works at Keihin is equipped to manufacture pipe as large as 609.6 mm in outside diameter in this way.

Spiral steel pipe

This steel pipe is made by forming hot rolled coil into a spiral shape and then welding the seams from inside and outside.

Bending steel pipe

Also called “plate bending” pipe, this pipe is made by gas cutting steel plate, bending the edges of the plate, and then forming into a tube shape by press bending.

UOE steel pipe

Steel pipe that is formed in two stages from plate - first bent into a “U” shape and then into an “O” shape - and then seam welded from inside and outside.