News Release

JFE Steel Corporation

JFE Steel Deploys "Teachingless" Robotic System

for Automated Steel Pipe Grinding at Chita Works

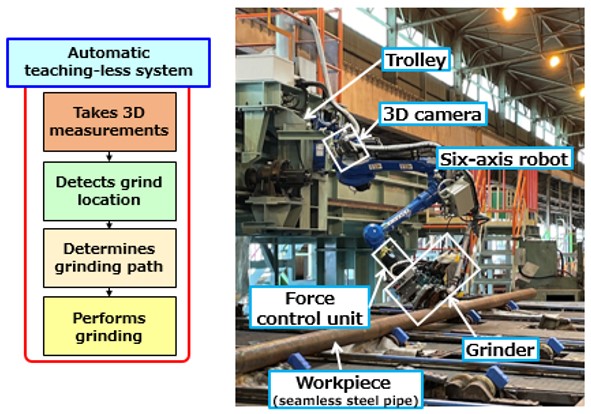

JFE Steel Corporation announced today that it has deployed a robotic system that uses advanced digital transformation (DX) and robotics technologies to automatically grind small-diameter seamless pipe at the company’s Chita Works. "Teachingless" technology enables the robot to fully and autonomously grind surfaces without the need for technicians to first teach it specialized tasks, such as how to detect tiny scratches and other defects, how to apply the grinder, etc. (Figure 1).

JFE Steel installed the robotic system at its Chita Works’ plant for small-diameter seamless pipe in May 2023 and recently put it into operation. So far, the system has been proven to speed up grinding operations by about 60% compared to conventional processes.

The company plans to deploy the system at other plants and for other processes to strengthen operational safety and raise productivity.

At the Chita Works, the system is being used to produce high-quality products by grinding out surface defects on finished and semi-finished items. Automating the grinding process is complicated by the fact that workpieces come in a multitude of shapes and sizes, and both work positions and defect types can vary widely. JFE Steel’s solution was to develop a technology capable of measuring the 3D shape of each workpiece, automatically detecting the positions of defects and then automatically calculating the corresponding robotic movements. In addition, grinding pressure, speed, etc. are optimized to achieve smooth surface cross sections and to appropriately adjust the amount of material to be ground off.

JFE Steel is constantly exploring ways to deploy automated and remote-controlled systems based on DX and robotics technologies, aiming to improve productivity and safety, particularly in the case of complex, dangerous and other high-load tasks. Grinding work is a relatively high-risk task involving the application of a disc-shaped abrasive tool rotating at high speed to metal surfaces. The company invested considerable time and effort in developing an automated technology to make the process safer.

JFE Steel will deploy the new robotic technology at other facilities within its Chita Works by FY2025, as well as at other plants for processes involving grinding.

JFE Steel is actively developing innovative DX technologies to make operations more productive, safe and stable. Looking ahead, the company hopes to address a wide range of issues through DX for a more sustainable world.

New Teach-less Robotic System

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 2,255 billion yen and consolidated crude steel output of 23.96 million tons in the fiscal year ended March 2021.

# # #