Earthquake-resistant line pipe

HIPER®

Safety and cost-saving for earthquakes and permafrost

For the steel pipe used in pipelines laid in areas prone to earthquakes and permafrost, high buckling resistance is needed, even in the face of deformation due to ground movement. To address these needs, JFE Steel made full use of its state-of-the-art materials design technology as well as its leading-edge “HOP®”(*2)on-line heat treatment plate system and “Super-OLAC®-A”(*3)accelerated cooling system at its West Japan Works (Fukuyama Area) Plate Mill, to develop its HIPER®, a world’s first groundbreaking high-strength steel pipe for pipelines that offers superior buckling resistance. This line pipe allows a substantial reduction in pipe thickness and results in both lower construction costs and improved safety, which is why HIPER®is now used for many pipelines that pass through areas subject to earthquakes and permafrost.

(*1)HIPER®: Abbreviation of Higher Performance for Earthquake Related Ground Movements

(*2)HOP:Abbreviation of Heat-treatment On-line Process. A system for on-line heat treatment of steel plate by means of induction heating. JFE Steel’s “Only One” leading-edge technology.

(*3)OLAC®:Abbreviation of On-Line Accelerated Cooling. An on-line accelerated cooling system with high cooling rate and high cooling precision. JFE Steel’s “Number One” leading-edge technology

Features

- ■Excellent resistance to buckling and deformation even when subject to ground movement

- ■High material uniformity thanks to “Super-OLAC®-A”

- ■Enables both lower pipeline construction costs and greater safety

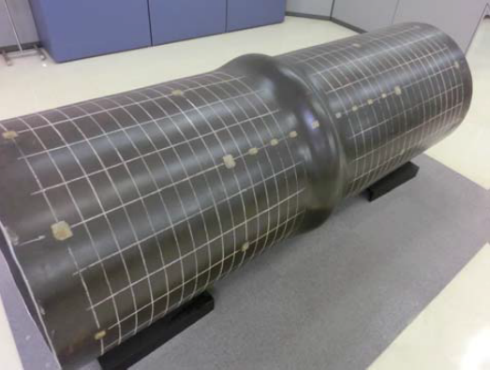

Photo: Buckling of steel pipe

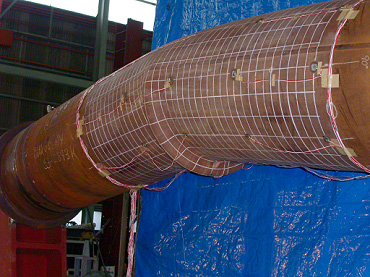

Photo: Buckling deformation of steel pipe after bending test

Applications

- Pipelines laid in areas prone to earthquakes and permafrost