News Release

JFE Steel Corporation

JFE Steel Develops Drone-mounted Gas Leak Detector

Avoids need for scaffolding when inspecting elevated

high-pressure gas pipelines

JFE Steel Corporation announced today that it has developed and deployed a flying gas-leak detector, called the Drone-mounted Gas/Air Leak Viewer, in collaboration with sister company JFE Advantech, which is now in use at all of its steelworks. The detector will improve the safety of inspecting elevated high-pressure gas pipelines, reduce related workload and further stabilize these inspection operations.

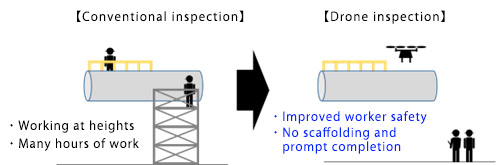

Various types of gases are used in steelworks to provide energy for production. In total, JFE Steel's facilities use hundreds of kilometers of such pipelines, which must be inspected periodically. The newly developed detector is the latest addition JFE Advantech’s line of Gas/Air Leak Viewer ultrasonic visualization devices. While manual inspection of elevated high-pressure gas pipelines has traditionally required the use of scaffolding, drones now allow personnel to safely perform inspections at ground level (Fig. 1).

Gas/Air Leak Viewers locate gas leaks by detecting the emission of ultrasonic waves that are inaudible to the human ear (Fig. 2). The technology combines sound-wave signals from multiple ultrasonic sensors to create a map that is then overlaid on an image of the facility, allowing people to pinpoint the location of a gas leak.

Since the noise generated by a drone’s propellers can make it difficult to accurately detect the location of a leak, the companies studied the acoustic characteristics of gas leaks and adopted a new ultrasonic sensor capable of taking measurements in a sound frequency band that makes it easy to distinguish between gas leaks and drone propellers. They also reduced the size and weight of the sensor for easy mounting on a drone, and developed a hood that reduces both propeller noise and aerodynamic drag (Fig. 3). The detector is equipped with a band-pass filter* to adjust the desired sound frequency depending on the environment.

JFE Steel is actively developing innovative digital-transformation (DX) technologies to realize more productive and stable operations, aiming to address a wide range of issues to increase its contribution to improving global sustainability.

*Used in electronic circuits, measurement devices and signal processing to allow a specific range of frequencies to pass through while attenuating all other frequencies

Fig. 1: Use of drone to inspect elevated gas pipeline

Fig. 2: Image captured by detector

Fig. 3: Gas leak detector mounted on drone

Related URL

JFE Group Solutions Business website: Gas Leak Viewer “MK-750ST”

https://www.jfe-steel.co.jp/en/products/solution/gasleakviewer/

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 2,255 billion yen and consolidated crude steel output of 23.96 million tons in the fiscal year ended March 2021.

# # #