Features 01

Problems that can be solved

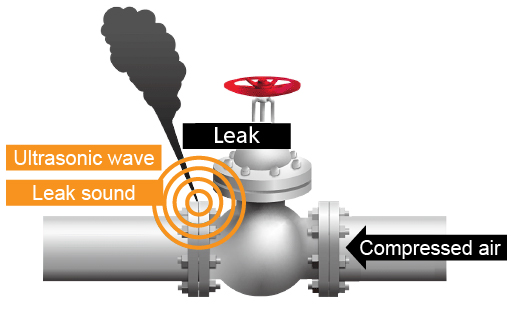

At manufacturing plants, many pipes are installed to distribute various gases, such as compressed air and fuel gas, to individual buildings and equipment. These pipes may have through-holes due to aging, corrosion, wall thinning, etc., causing internal gas leaks. Until now, checking and confirming gas leaks was a time-consuming process that relied on human senses, such as listening to sounds and spraying soapy water. In addition, gas leak inspection work for overhead piping required setting up of scaffolds and use of an aerial work platform.

Gas Leak Viewer MK-750ST is a detector that instantly identifies the location of a gas leak by simply pointing the main unit at the target equipment. This device can also accurately identify distant locations that are as far away as 10-20 m*.

* The leak detection distance depends on the amount of gas leaked.

Features 02

Technology highlight

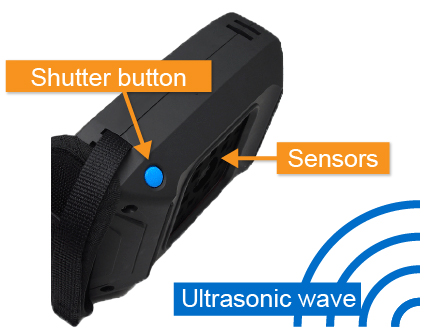

The MK-750ST identifies the direction of a gas leak by arranging multiple ultrasonic sensors in a flat plane and calculating the slight difference in arrival time of the ultrasonic waves. The leak location is displayed on the screen by superimposing the identified location on the image from a high-resolution visible camera installed on the same plane as the ultrasonic sensors.

In addition, the amount of leak is calculated and indicated using a sound pressure value (ultrasonic strength). As the ultrasonic sensors used are not affected by audible noise, the device can detect gas leaks even in noisy environments.

The patented technology also minimizes the number of sensors, thereby reducing the size and weight of the main body.

Features 03

Application example

・Gas leaks through holes of piping

・Gas leaks from a flange

・Gas leaks from a joint

・Gas leaks due to poor welding

・Gas leaks from a crack in the hose

・Gas suction into the vacuum piping

* Any type of gas can be detected, including air, vapor, nitrogen, argon, etc.

* Very small leaks may not be detected.

① Start measurement by turning the power on

② Face “MK-750ST” toward the target equipment

③ Detect gas leaks

* To save the image, press the shutter button.

The device detects a gas leak in piping, etc.,

The device detects a gas leak in piping, etc.,

Solution business

Solution business