News Release

JFE Steel Corporation

JFE Steel’s New Insulated Pure-iron Powder for Soft Magnetic Composites

Enables Prototype Axial-gap Motor to be Slimmed Down by 48%

JFE Steel Corporation announced today that, together with JFE Techno-Research Corporation and Armis Corporation, a company formed by Shizuoka University, it has used the JFE Steel-developed insulation-coated pure-iron powder Denjiro® to design, prototype and test an axial-gap motor that achieves the same power as larger radial-gap motors and is 48% thinner and 40% lighter than comparable axial-gap motors.

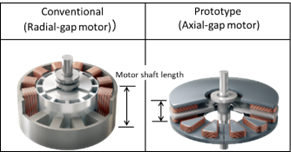

Increasingly popular thin axial-gap motors, also known as pancake motors, use magnetic-flux paths parallel to the motor’s axis of rotation to achieve a smaller form factor than conventional radial-gap motors (Fig. 1).

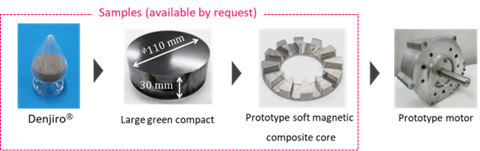

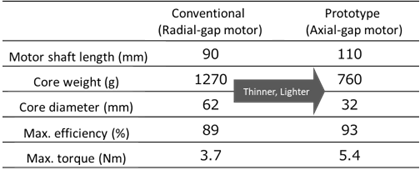

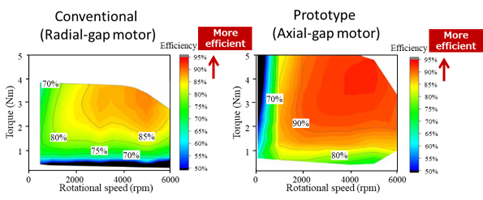

The three companies designed, prototyped and tested an axial-gap motor incorporating a soft magnetic composite core made of Denjiro® (Fig. 2), which JFE Steel announced as a new insulation-coated pure-iron powder on January 27, 2022 (see URL below). The initiative demonstrated that small cores made with Denjiro® enable axial-gap motors to be made significantly slimmer and lighter, yet as efficient or even more efficient than conventional motors (Table 1 and Fig. 3).

JFE Steel and JFE Techno-Research are now shipping samples of large, 110mm-diameter green compacts for cutting and machining soft magnetic composite cores, as well as prototype soft magnetic composite cores conforming to specific designs.

There is a growing demand for smaller, more efficient motors for industrial equipment and automobiles that contribute to carbon neutrality. However, the conventional practice of making three-dimensional magnetic cores from laminated electrical steel sheets has proved difficult. The solution was to use Denjiro®, because it can be compacted into cores with three-dimensionally uniform magnetic properties and accommodate complex shapes in axial-gap motors.

Denjiro® is an excellent example of JFE Steel’s commitment to working closely with customers to meet the demanding needs of the industrial world, taking full advantage of the company’s advanced materials. It also reflects JFE Steel’s ongoing efforts to provide increasingly environmentally friendly products capable of reducing CO2 emissions and ultimately leading to a more sustainable world.

Figure 1: Types of motors

Figure 2: From powder to prototypes

Table 1: Conventional vs. prototype motor (test results)

Figure 3: Efficiency of conventional vs. prototype motor

Related URL

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 2,255 billion yen and consolidated crude steel output of 23.96 million tons in the fiscal year ended March 2021.

# # #