News Release

JFE Steel Corporation

JFE Steel’s New “FLExB® Welding” Method Improving Fatigue Resistance

of Steel Structures

JFE Steel announced today that it has developed a new welding method, named FLExB® Welding1, capable of improving the durability of bridges or other steel structures. The method was registered (CB-230007-A) in the New Technology Information System (NETIS) of Japan’s Ministry of Land, Infrastructure, Transport and Tourism in May.

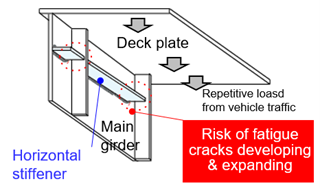

Reducing the costs of age-related maintenance and renewal is crucial for steel structures that have lengthy service lives. Bridges, in particular, are repeatedly subjected to loads that raise the risks of fatigue crack initiation in welded sections (Figure 1).

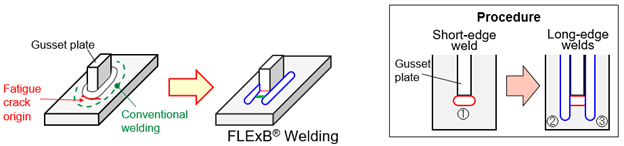

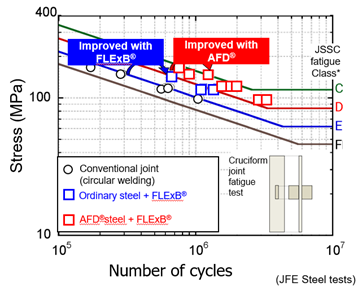

In the FLExB® Welding, the shorter sides of edges in joining members, called gusset plates, are welded and then the longer sides of edges are welded with a sandwich-like configuration and its beads are extended to plate side (Figure 2). From the result of the weld configuration, stress concentration on points where fatigue cracks typically appear in welded sections is reduced and fatigue crack initiation and propagation can be suppressed. We confirmed one-class improvement in the JSSC2 fatigue class3 rating in the fatigue test of weld joints using FLExB® Welding (Figure 3).

The new technology also improves the efficiency of welding construction compared to conventional methods. In addition, it can omit needs for surface treatments and other processes that are conventionally required as a post-weld treatment to improve fatigue strength. Moreover, combining FLExB® Welding with JFE Steel’s AFD®4 steel-plate products can further enhance fatigue resistance.

JFE Steel is committed to developing high-performance steel materials and welding methods that contribute to the durability, safety and economic viability of bridges, ships, construction machinery, industrial machinery and other steel structures capable of contributing to a more sustainable world.

1 FLExB®: Fatigue Life Extended Bead

2 JSSC: Japanese Society of Steel Construction.

3 Fatigue class: Measure of resistance to fatigue damage, with classes running in alphabetical order from highest to lowest.

4 AFD®: Anti-Fatigue Damage. Steel plate products offering enhanced resistance to fatigue.

Related URL

Figure 1: Example of bridge fatigue crack initiation sites and optimal FLExB® welding sites

Figure 2: FLExB® Welding

Figure 3: FLExB® welded joint load stress vs. Number of cycles (SN diagram)

(according to JFE Steel’s tests)

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 2,255 billion yen and consolidated crude steel output of 23.96 million tons in the fiscal year ended March 2021.

# # #