News Release

JFE Steel Corporation

JFE Steel Develops Thin, Fatigue-resistant Steel for Increased Bridge Safety

JFE Steel announced today that it has developed a thin version of its AFD® (anti-fatigue-damage) steel with improved fatigue resistance. Compared to existing AFD steel, the thin-walled version is expected to be deployed in a wider range of applications, including bridge structural members that are prone to cracking over time. The new product has been registered (KT-220231-A) in the New Technology Information System (NETIS) that is managed by Japan’s Ministry of Land, Infrastructure, Transport and Tourism.

The thin AFD steel is produced at the Keihin facility of JFE Steel’s East Japan Works using the Super-RQ system with advanced cooling control, which is part of a plate mill that started operating in March 2020. The steel plate, which has a minimum thickness of 9mm, retains the mechanical properties of conventional plates while offering improved fatigue resistance. This plate meets the standards for rolled steel used in bridges, including welded structures (JIS G3106 SM490) and high-yield-strength steel plate (JIS G3140 SBHS500).

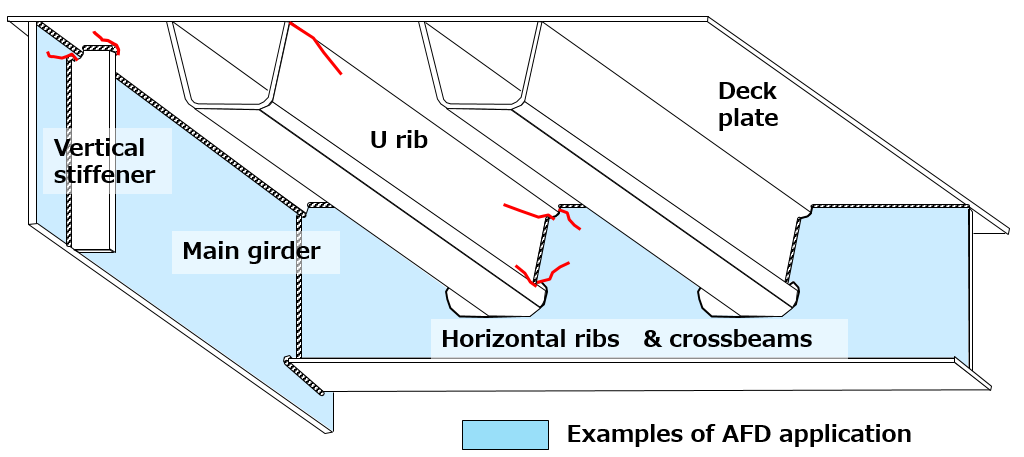

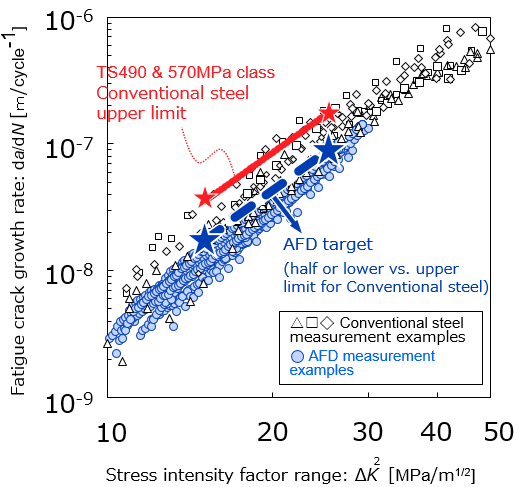

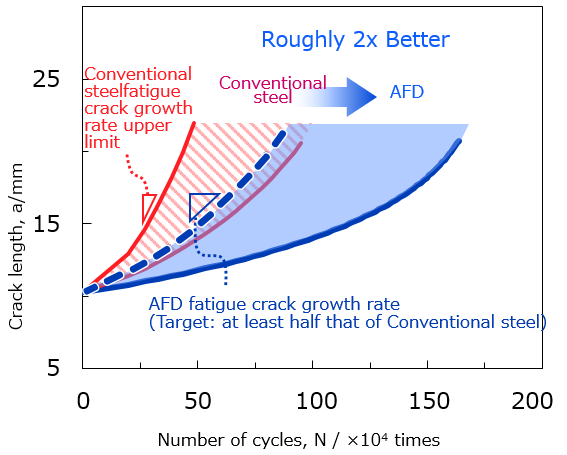

For steel structures purposed for long-duration use, ensuring low maintenance and renewal costs associated with aging is crucial. Thin-walled members of bridges are susceptible to fatigue cracking over time and such cracks are at risk of increasing in size between inspections and maintenance (Figure 1). JFE Steel’s thin fatigue-resistant steel is ideal for such structural members, including because AFD already reduces the fatigue-crack growth rate1 to half or less of the upper limit of ordinary steel and roughly doubles product life compared to ordinary steel (Figures 2 and 3), both of which reduce lifecycle costs associated with long service life.

Going forward, JFE Steel will continue to improve the performance and quality of steel materials to achieve superior durability, safety and economy in steel structures such as bridges, ships, construction machinery and industrial machinery, thereby contributing to a more sustainable world.

1 Fatigue damage is caused by small, repeated forces that create cracks that grow gradually grow until the material fails. Since such cracks propagate incrementally with repeated application of force, the length over which the cracks propagate per repetition is called the fatigue crack growth rate. Improving the properties of steel materials and delaying the growth of such cracks can help to prevent structural failure.

Figure 1: Examples of thin AFD steel application

Figure 2: Distribution of fatigue crack growth life in Conventional steel and AFD

2 Stress intensity factor ΔK: Expresses the distribution of stress near the tip of a crack. The larger the value, the more readily the crack will progress.

Figure 3: Calculation of fatigue crack growth life in Conventional steel and AFD

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 2,255 billion yen and consolidated crude steel output of 23.96 million tons in the fiscal year ended March 2021.

# # #