News Release

JFE Steel Corporation

JFE Steel Deploys Data Science-Based Equipment Anomaly Detection System

at All Hot-Rolling Mills

—Designed to improve productivity by preventing equipment faults—

JFE Steel Corporation announced today that it has deployed the J-dscom® system, which uses the latest data science technologies to detect signs of equipment anomalies at its steelworks and hot-rolling mills. The company plans to roll out the system for other manufacturing processes going forward to prevent equipment issues ahead of time and thereby boost productivity.

The system has effectively reduced faults equivalent to over 50 operational hours per annum (over 30,000 metric tons of steel production) at the hot-rolling mill in JFE Steel’s West Japan Works in the Kurashiki District, where it was first deployed back in FY2018. So far, the company has installed the system at all of the hot-rolling mills in its West Japan Works (Kurashiki and Fukuyama Districts) and East Japan Works (Chiba and Keihin Districts). JFE Steel is working to build an optimal model across the entire company by deploying the same system in all locations, making it easy to share fault-monitoring models. Going forward, it will also utilize the system for its other manufacturing processes, including iron- and steel-making.

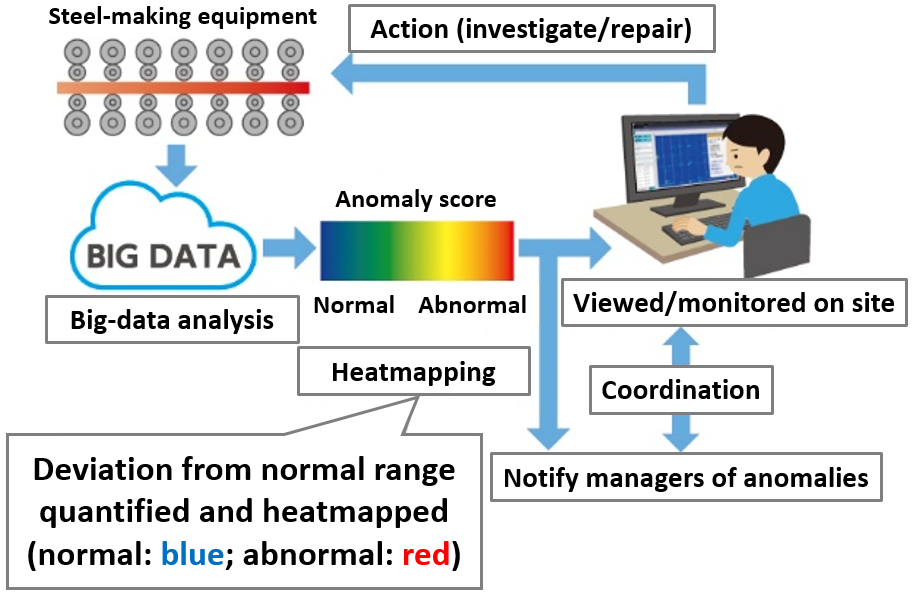

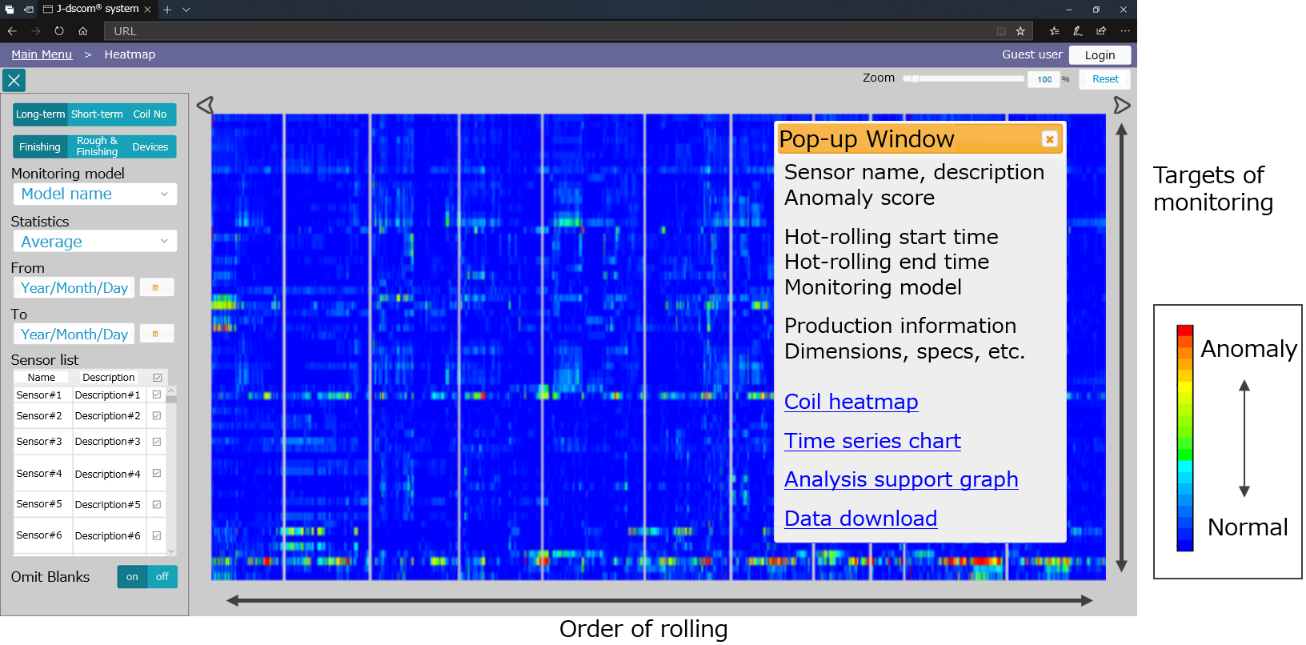

This system uses big-data analysis techniques to efficiently and comprehensively analyze vast amounts of data on operating conditions, including electrical current, pressure, flow rate, temperature, and vibration. It produces an anomaly score that indicates the degree of deviation from the normal baseline, making it possible to prevent not only the sort of faults that have previously occurred but also unexpected issues (Figure 1). Moreover, it is possible to immediately identify the part of equipment or system component experiencing an anomaly by using the heatmap display where the magnitude of anomaly score is mapped over time (Figure 2).It helps engineers to take appropriate maintenance action.

JFE Steel aims to make innovative productivity gains and achieve operational stability by actively engaging in DX (digital transformation), including opening the JFE Digital Transformation Center (JDXC®) and deploying CPS (cyber-physical systems) at its steel mills and across the company as a whole. JFE Steel continues to contribute toward building sustainable societies by finding solutions to issues facing all aspects of manufacturing through DX.

Figure 1: J-dscom® system’s anomaly detection process

Figure 2: Multipoint monitoring using heatmap

Related press release

JFE Steel Initiating Company-wide System for Detecting Signs of Equipment

Anomalies Using Data Science Technology

—Aims to improve productivity by preventing faults before they occur—

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 2,255 billion yen and consolidated crude steel output of 23.96 million tons in the fiscal year ended March 2021.

# # #