Features 01

Expected Problems

・Aren't you bothered by overlooked flaws and miss-detection due to the difficulty of distinguishing flaws from the surface pattern?

・Doesn't visual inspections place a heavy work load on the operators?

・Isn't management/sharing of flaw position information time- and labor-intensive work?

Features 02

Technology highlight

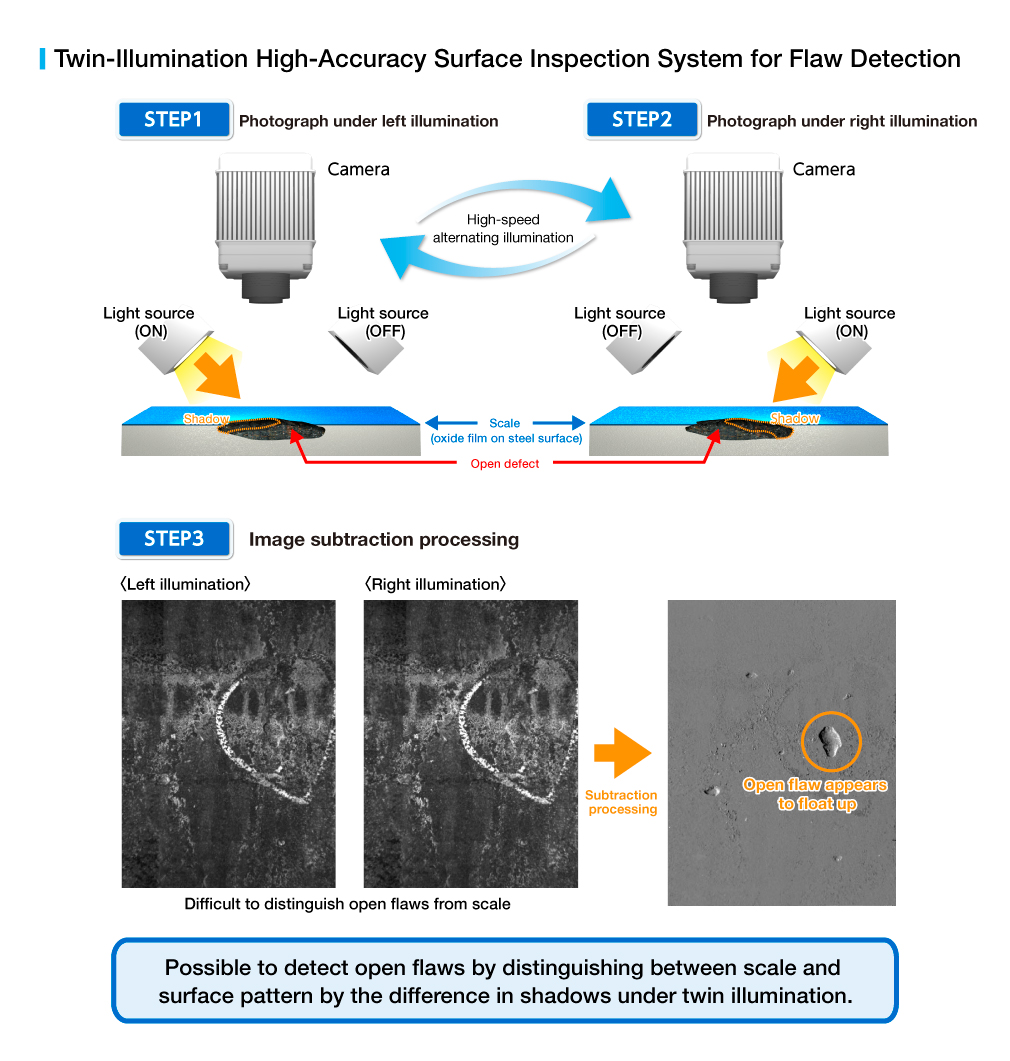

・Utilizes the fact that the surface pattern area is flat, while dents and other surface flaws are concave/convex.

・Photography is performed while alternately illuminating light from 2 directions ("twin illumination") at high speed.

・Possible to emphasize and detect only concave/convex flaws with a large shadow difference by image subtraction processing.

・Flaw information is digitized by on-line automatic detection.

Features 03

Proposed Solutions (Examples)

・Integrated supply of detection mechanism/control system to existing production lines where surface inspection of steel strips, etc. is necessary.

*Because this technology has been optimized as a system, it is difficult to sell the component functions separately.

Solution business

Solution business