News Release

JFE Steel Corporation

JFE Steel’s New Welding Method for Built-up H Beams

Enables Rationalized Production and Achieves Superior Seismic Performance

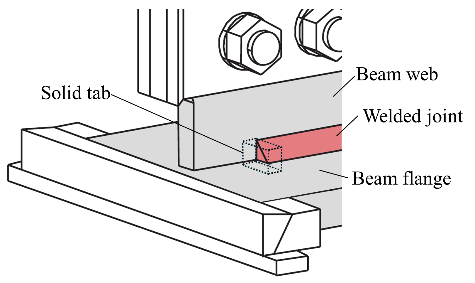

JFE Steel Corporation today announced a new, rationalized welding method for built-up H-shaped steel beams (BH beams), developed in collaboration with National University Corporation Utsunomiya University, Nihon Sekkei, Inc., and Yonemori Corporation. This innovative method, named smarTABH® (Figure 2), in addition to eliminating the need for conventional scallop1 back welding and processing of beam end joints (Figure 1), also improves the seismic performance of structures. Recognizing the production, design and structural-performance advantages, the General Building Research Corporation of Japan (GBRC) has awarded the new method a Building Technology Performance Certification (GBRC No. 24-29).

BH beams are fabricated by welding three steel plates together to form an H-shaped cross section. BH beams, which enable the construction of larger structural dimensions than rolled H beams, are used in high-rise buildings and other structures requiring superior seismic performance. The smarTABH® method can be used for end welds of BH beams produced using groove-first fabrication (Figure 3), one of the two main fabrication methods, the other being the pre-assembly method.

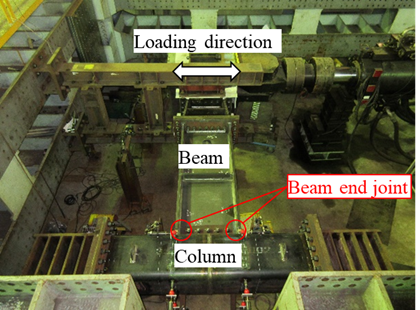

With the smarTABH® method, welding is performed up to solid tabs placed near the scallop area [Figure 2(c)]. This creates a larger flexible area2 at the beam flange, which realizes greater plasticity than conventional methods3 to mitigate concentrated stress and strain during seismic events. The load-bearing capacity and plastic-deformation performance of BH beam-end joints achieved with the smarTABH® method have been verified through structural testing and finite element analysis (Figure 4).

Steel plates that can be used as BH beams in combination with the new method include JFE’s heavy plates, such as SN490 and HBL®385. The method is applicable to beam sections with flange thicknesses up to 40 mm and does not restrict beam height or width, making it suitable for a wide range of uses. The method can also be used for BH beams with widened flange ends.

Going forward, JFE Steel will continue developing and promoting highly value-added building materials and technologies to meet diverse customer needs, aiming to strengthen nationwide infrastructure for improved safety and reliability in an increasingly sustainable world.

1 A notch provided to prevent welding lines from intersecting when steel plates are welded together in a cross pattern.

2 The area in the beam flange base metal where plastic deformation occurs between the end of the beam flange weld and the toe of the fillet weld (between the beam flange and beam web) due to external forces such as earthquakes.

3 Based on “Study on verification methods for the safety of steel structures against long-period ground motions,” Ministry of Land, Infrastructure, Transport and Tourism, FY2012 Building Standards Development Project (April 2013).

| (a) Location of beam end joint | (b) Conventional beam end joint specifications |

|

|

| Column Beam end joint Beam |

Scallop Back weld and finishing process Beam web Welded joint Beam flange |

| (a) Without unwelded area | (b) With unwelded area | (c) Installation example |

|

|

|

| Solid tab Beam web Welded joint Beam flange |

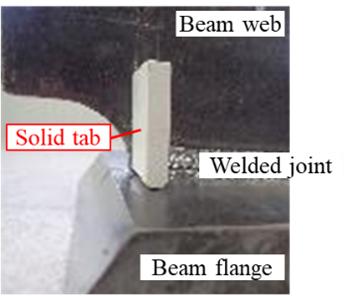

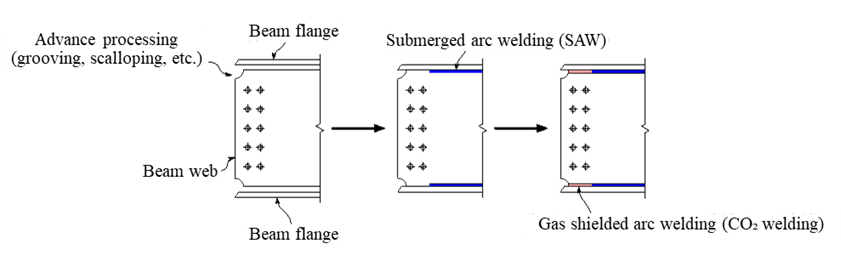

Figure 3. Examples of BH Beam Types and Fabrication Processes

(a) Pre-assembly Type: Three steel plates are assembled as an H bean by welding, and then scalloping or other processing is performed

Beam flange

Beam web

Submerged arc welding (SAW)

Cut to specified length

Various processing (grooving, scalloping, etc.)

(b) Groove-first Type: After scallop cutting and other processing, three steel plates are welded together as an H beam.

Advance processing (grooving, scalloping, etc.)

Beam flange

Beam web

Submerged arc welding (SAW)

Gas shielded arc welding (CO2 welding)

| (a) Loading conditions | (b) Test results and design fatigue curve |

|

|

| Loading direction Beam Column Beam end joint |

Plastic ductility (μ) No. of cycles until fracture Conventional method (design) Conventional method (test) New method (design) New method (test) Present method (test results) |

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. Under the corporate vision of “contributing to society with the world’s most innovative technology,” JFE Steel leverages world-class technologies and know-how to produce a wide range of products. The company reported consolidated sales of 3,716 billion yen and consolidated crude steel output of 24.80 million tons in the fiscal year ended March 2023.

# # #