News Release

JFE Steel Corporation

JFE Steel Begins Introducing CPS Technology into Sintering Process

Aiming to stabilize sinter quality, increase productivity and lower GHG emissions

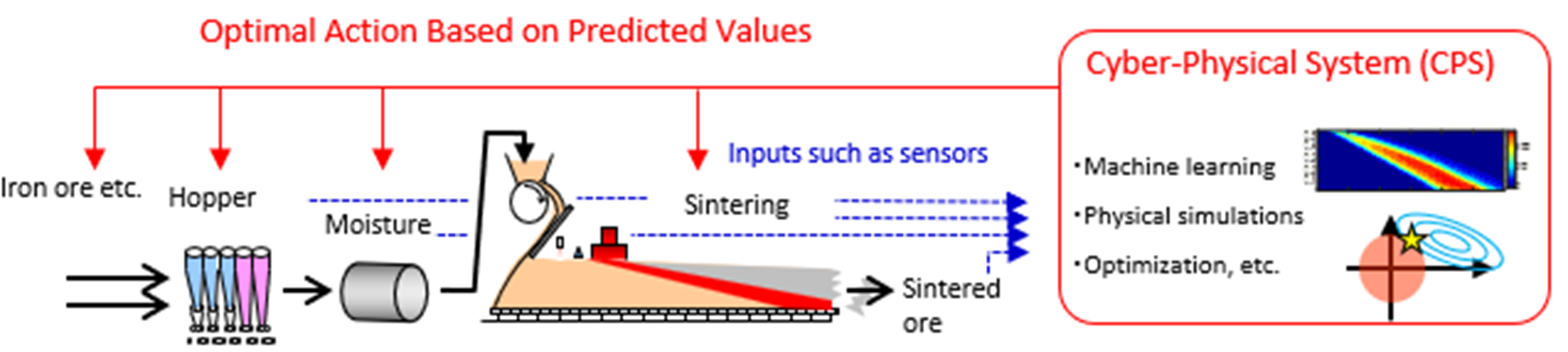

JFE Steel announced today that it is deploying Cyber-Physical Systems (CPS1) technology at its seven sinter production facilities in Japan. The initiative will enable the company to develop advanced predictive models for its sintering process by leveraging digital technology for increasingly innovative steelmaking. JFE Steel expects the change to yield significant results, including stabilized sinter quality, improved productivity and reduced greenhouse gas (GHG) emissions.

As part of its digital transformation (DX) strategy, JFE Steel will deploy CPS technology at all sintering facilities to create intelligent steelworks. CPS is being implemented across all manufacturing processes to build core CPS systems for each facility, as well as for company-wide integration. CPS deployment for all blast furnace processes has already been completed.

The newly introduced CPS system is used to sinter iron ore fines at high temperature to transform them into sintered ore with the necessary strength and chemical properties for use in blast furnaces. The quality of the sintered ore directly impacts blast furnace stability and the production of high-quality steel. Although quality is strictly managed based on multiple indicators, quality control and operational decisions often rely on the knowledge and experience of operators. Conventionally, this creates difficulties in balancing the assurance of sintered ore quality with production efficiency.

Introducing a CPS into the sintering process has enabled JFE Steel to develop an advanced predictive model. The model integrates a newly constructed statistical model, which is based on extensive sensor data collected from each production site, and a physical model that simulates thermochemical reactions. Conducting real-time operational simulations in the digital space enables the efficient prediction of future operating conditions. The result is stable quality, improved productivity and reduced GHG emissions due to reduced coke usage for heating during sintered ore production.

To prevail in global competition within the steel industry, JFE leverages its extensive data assets together with the latest data science and AI technologies, including introducing CPS technology into all manufacturing processes.

1 Sensor data collected from physical manufacturing processes is analyzed using AI, then virtual (cyber) processes are recreated in a digital space using proprietary methods, and finally the two are connected in real time. This virtual process reveals internal equipment states that are invisible in reality and predicts future states. Applying the results of status monitoring and anomaly prediction to actual processes promotes more stable operations and improved productivity.

Sintered CPS

Intelligent Steel Plant

Related press releases:

Reference:

JFE group DX report 2024

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. Under the corporate vision of “contributing to society with the world’s most innovative technology,” JFE Steel leverages world-class technologies and know-how to produce a wide range of products. The company reported consolidated sales of 3,716 billion yen and consolidated crude steel output of 24.80 million tons in the fiscal year ended March 2023.

# # #