News Release

JFE Steel Corporation

JFE Steel Launches Breakout Detection System for Continuous Casters

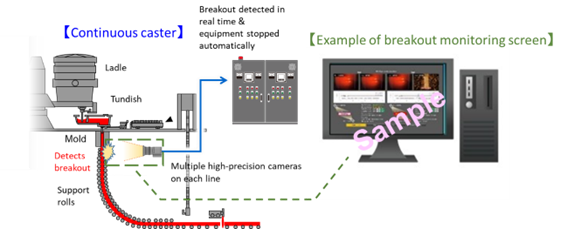

JFE Steel announced today that it has launched its Breakout Detection System to prevent continuous slab casters at steelworks from experiencing situations known as breakouts in which the surface of a cooling slab breaks and molten steel escapes, often resulting in damaged equipment. Developed by JFE Steel, the system uses cameras and an image-analysis system to monitor the slab inside a continuous caster for the early detection of possible breakouts and to promptly stop the caster if such a condition is detected.

JFE Steel has installed the system in its 10 main continuous casters, automating the process of an on-site operator watching for a breakout and manually stopping the caster if required. The Breakout Detection System has been proven to significantly reduce the time required to stop equipment in potential emergencies, thereby reducing the amount of molten steel that could potentially escape as well as shortening equipment recovery times and minimizing equipment damage caused by molten steel.

JFE Steel is now launching the Breakout Detection System for use by other steelmakers, aiming to promote its adoption among a wide range of potential customers worldwide.

In the upstream steelmaking process, continuous slab casters are used to cool and solidify refined steel into slabs. If a breakout occurs during this process, it can have a severe impact on the operation of equipment. Although conventional systems exist for breakout prediction and prevention, the reliable prevention of such accidents has proven difficult, so steelmakers have long sought a better solution to minimize the risk of equipment damage.

Figure: Breakout Detection System

Tundish: vessel for transferring molten steel from ladle to mold

The Breakout Detection System analyzes images from multiple high-precision cameras installed under the continuous caster mold to determine early-stage breakouts in real time. If an anomaly is detected, a signal is immediately sent to the continuous caster control system to automatically stop specific functions as required. System configuration includes special measures to avoid counterproductive false positives. The Breakout Detection System comes with a complete set of high-precision cameras and an image-analysis system.

JFE Steel, which is implementing various digital transformation (DX) initiatives, is striving to achieve better quality, labor productivity and yields as well as grow hand in hand with other steelmakers by providing solutions realized with the company’s advanced technologies and expertise for enhanced steelmaking operations.

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 2,255 billion yen and consolidated crude steel output of 23.96 million tons in the fiscal year ended March 2021.

# # #