News Release

JFE Steel Corporation

Novel Processes for Manufacturing Valuable Materials Using Coal-Derived CO2 Selected for NEDO Projects

JFE Steel Corporation announced today that it was selected by the New Energy and Industrial Technology Development Organization (“NEDO”) for the research and development (R&D) of novel processes to manufacture utilizable materials using CO2 emitted from coal-using industries. The R&D was selected as part of a public solicitation for the NEDO project “Development of Technologies for Carbon Recycling and Next-Generation Thermal Power Generation/Development of Technologies for CO2 Reduction and Utilization.” The furthering of R&D will be conducted in collaboration with the Research Institute of Innovative Technology for the Earth (“RITE”) and Ehime University.

The objective of the R&D is the massive reduction of CO2 emissions through measures such as effectively utilizing by-products such as combustible gas from blast furnace gas and slag produced in the manufacturing of iron.

JFE Steel has positioned efforts to deal with climate change as its most important management issue, and is striving to be carbon neutral by 2050. Moving forward, JFE Steel will also contribute to the realization of a sustainable society by promoting multi‐track technological development of various innovative technologies.

R&D (1): “Development of Optimum System for Methanol Synthesis Using CO2”

1. Technical Field

Development of technology for the use of CO2 in chemical products

2. Proposers

JFE Steel Corporation and RITE

3. Project Period

FY2021 to FY2025

4. Summary

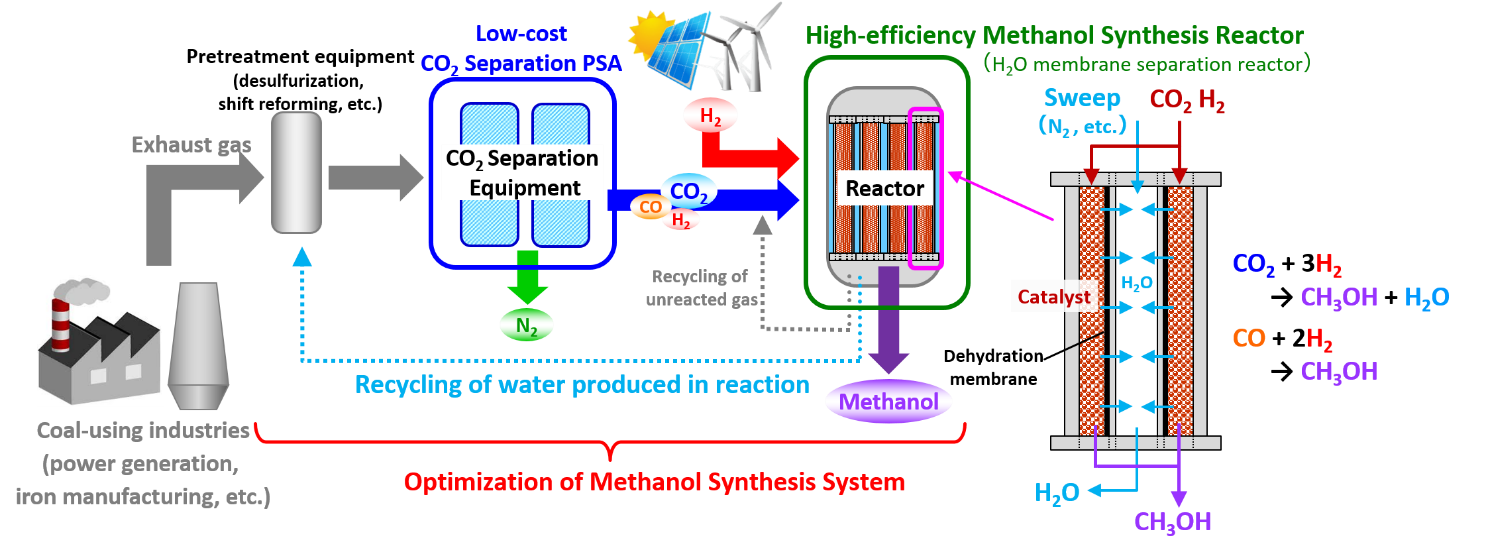

A process for effective utilization of CO2 to synthesize basic chemical product methanol from CO2 in exhaust gas emitted from ironworks, etc., will be developed. Blast furnace gas from ironworks has a relatively high concentration of CO2 and contains CO and H2 as secondary components, and thus, the project aims to synthesize methanol with higher efficiency and lower cost by maximally utilizing the CO2 and secondary components. In this project, we will advance the development of technology for low-cost CO2 separation by pressure swing adsorption (PSA)*1 and technology for an H2O membrane separation reactor*2 that enables high-efficiency methanol synthesis from CO2, as well as the construction of an entire optimal system including pretreatment equipment and the recycling of water produced in the reaction when methanol is synthesized.

*1 Pressure Swing Adsorption (PSA)

A method for separating gases using a phenomenon in which the gas adsorption amount of the adsorbent such as zeolite, a type of clay mineral, and activated carbon, changes depending on gas pressure. The adsorbent and operating pressures are selected according to the type of gas to be separated.

*2 H2O membrane separation reactor

A methanol reactor based on a novel method whereby high reaction efficiency can be obtained by synthesizing methanol while separating and removing water produced in the reaction of methanol synthesis from CO2, using a specific zeolite membrane developed by RITE with H2O selective permeability. This reactor is now being developed jointly by JFE Steel and RITE.

5. R&D Items

(1) Development of Low-cost CO2 Separation PSA (JFE Steel).

(2) Development of High-efficiency Methanol Synthesis Reactor (H2O membrane separation type reactor) (JFE Steel)

(3) Development of Practical Dehydration Membrane (RITE)

(4) Optimization of Methanol Synthesis System (JFE Steel)

R&D (2): “Research and Development of Innovative CO2 Fixing Technology through Quick, Large-quantity Carbonation of Steel Slag”

1. Technical Field

Development of technology for the use of CO2 in concrete, cement, carbonates, carbon, carbides, etc.

2. Proposer

JFE Steel Corporation

3. Joint Partner

Ehime University

4. Project Period

FY2021 to FY2025

5. Summary

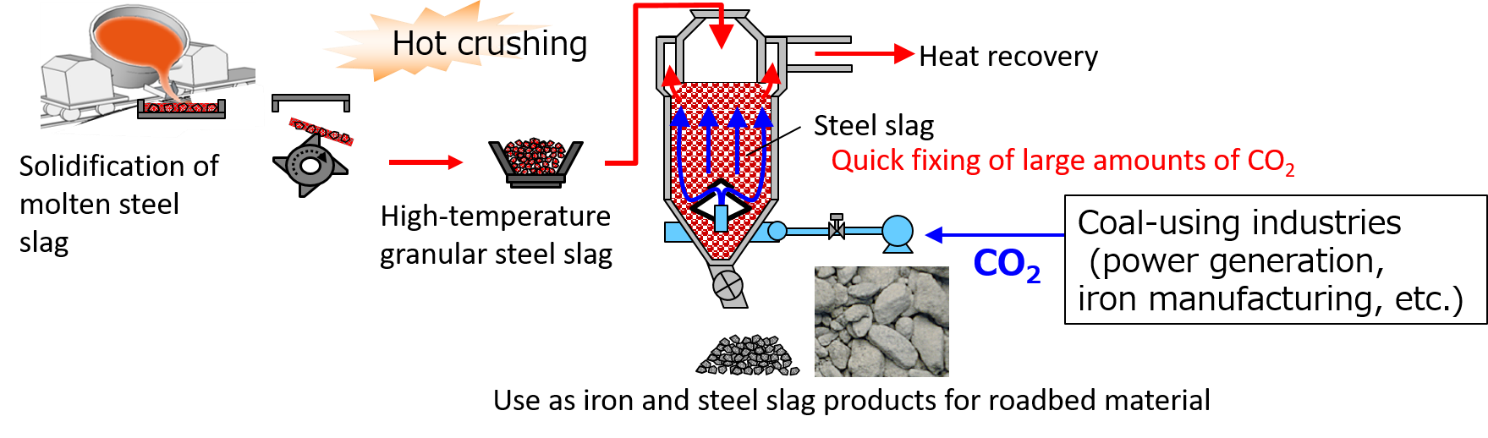

With the aim of fixing large amount of CO2 in a short amount of time, we will develop an innovative technology to convert calcium oxide in steelmaking slag, which is a by-product of steel production, into carbonates*3 by blowing CO2 emitted from coal-using industries into high-temperature steelmaking slag.

At the same time, by recovering the heat of the gas after CO2 fixation, energy efficiency will be improved and the amount of CO2 fixation and reduction is maximized throughout the process. We aim to use the steel slag converted to carbonates for roadbed material, which is in high demand.

*3 Carbonate

A general term for ionic crystalline substances containing carbonic acid ions (CO32-). Calcium carbonate (CaCO3), which is a compound of CO2 and calcium oxide (CaO), is a typical carbonate and is the main component of limestone.

6. R&D Items

(1) Development of technology for Quick, Large-quantity Carbonation of Steel Slag (JFE Steel)

(2) Clarification of slag carbonation mechanism (JFE Steel/Ehime University)

(3) Development of heat recovery technology (JFE Steel)

(4) Development of molten steel slag solidification and hot crushing technology (JFE Steel)

(5) Evaluation of hot crushed and carbonized slag as iron and steel slag for roads (JFE Steel)

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 2,255 billion yen and consolidated crude steel output of 23.96 million tons in the fiscal year ended March 2021.

# # #