News Release

JFE Steel Corporation

JFE Steel 1.5 GPa-Grade High-Tensile Strength Cold-Rolled Steel Sheets Adopted for First Time in Vehicle Body Structural Parts

JFE Steel Corporation announced today that its 1.5 GPa-grade (1470 MPa) high-tensile strength cold-rolled steel sheets are now being utilized in vehicle body structural parts, the world’s first such adoption in a cold press forming application (based on an internal examination). This constitutes the highest strength of vehicle body structural parts obtained through cold press forming. The steel sheets are being utilized in several applications by automakers, and JFE Steel has begun supplying these sheets to auto parts suppliers.

In order to protect vehicle occupants in the event of a collision and improve fuel economy through weight reductions, efforts are ongoing to increase the strength of vehicle body structural parts. JFE Steel’s 1.5 GPa-grade high-tensile strength cold-rolled steel sheets are already being utilized in parts with simple shapes, such as bumpers and door impact beams. However, the adoption of high-tensile strength cold-rolled steel sheets for vehicle body structural parts with complex shapes has been limited to the 1310MPa grade until now, because increasing the strength of sheets can result in decreased cold press formability and delayed fracture resistance.1

To overcome with these issues, the adoption of 1.5 GPa-grade high-tensile strength steel sheets through a hot press forming process2 is becoming more widespread. However, this requires the steel to be heated to high temperature and then maintained at constant temperatures for cooling, which decreases the number of parts that can be pressed per unit of time. Improvements have therefore been desired from a number of perspectives, including manufacturing costs.

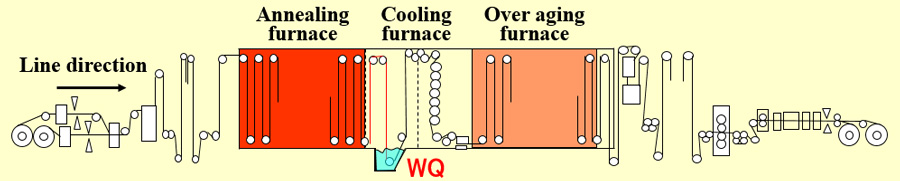

With the new 1.5 GPa-grade steel sheets, the high cooling capacity of the proprietary WQ (water quenching) method-based continuous annealing process line located at JFE’s West Japan Works (Fukuyama District) was used to reduce the addition of alloy elements and minimize non-uniformity of the steel sheet microstructure (Fig. 1). As a result, particularly high yield strength3 and delayed fracture resistance were simultaneously realized even with the 1.5 GPa-grade high-tensile strength steel sheets while maintaining cold press formability equivalent to that of 1310 MPa-grade sheets. This enabled the utilization of the 1.5 GPa-grade high-tensile strength steel sheets in vehicle body structural parts through a low-cost cold press forming process.

The superiority of the newly adopted steel sheets in terms of their strengths, delayed fracture resistance and cold press formability was recognized by automakers, and application technology was developed in a joint effort between JFE Steel and various automakers. These efforts have culminated in the deployment of the steel sheets in the manufacture of vehicle body structural parts.

Going forward, JFE Steel will endeavor to expand the range of application of these steel sheets as well as to further develop high-performance high-tensile strength steel sheets. JFE Steel is pleased to contribute to the realization of a sustainable society by supporting the development of safe, environmentally friendly vehicles.

Fig. 1 Schematic diagram of the WQ method-based continuous-annealing equipment

1 A property that inhibits the occurrence of static brittle cracking attributed to hydrogen after press molding

2 A process in which a material is heated to a high temperature and softened, and is then simultaneously molded with a press die and quenched to obtain a high-strength part. The hot pressing process can reduce residual stress due to press molding, and is therefore advantageous for ensuring delayed fracture resistance

3 The strength at which a steel sheet begins to deform. The yield strength directly impacts the strength of a part.

About JFE Steel Corporation

JFE Steel Corporation, one of the world’s leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 3,900 billion yen in 2018 and consolidated crude steel output of 27.88 million tons in the fiscal year ended March 2019.

# # #