Features 01

Features of Spectral Principal Component Radiation Thermometer

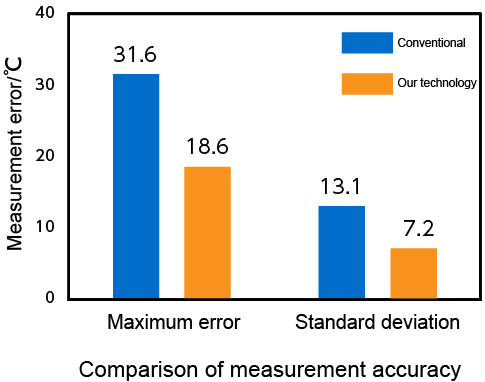

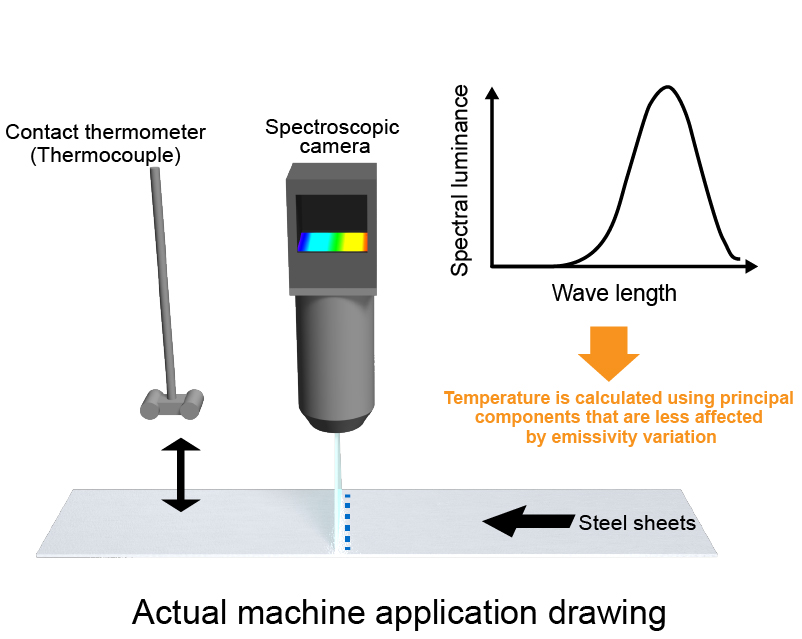

This instrument reduces measurement errors due to emissivity variations, which have plagued the measurement using conventional radiation thermometers.

This enables temperature measurement across the entire length of the plate, even in the annealing furnace of stainless steel, contributing to the improvement of quality control and productivity.

Measurement errors can be reduced even in a high temperature range with large emissivity variations.

Features 02

Technology highlight

A spectroscopic camera is used to obtain the spectral emission spectrum.

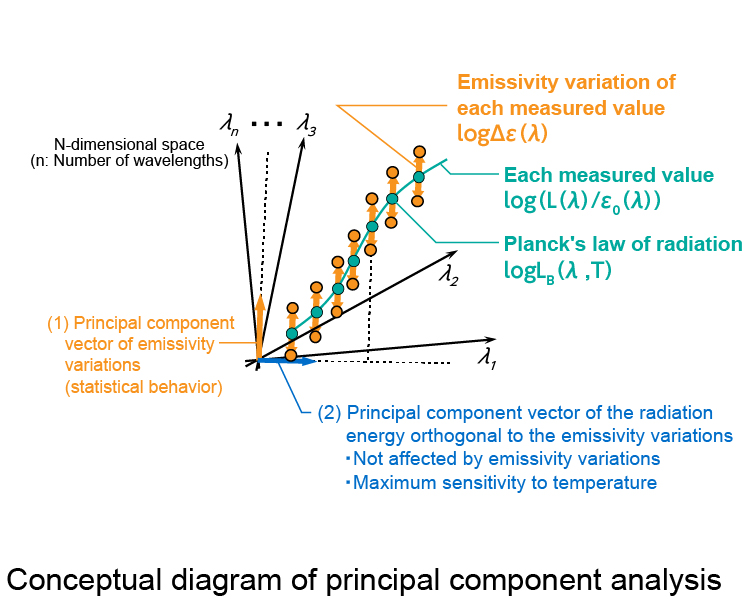

Principal component analysis, one of the data science methods, is used.

Those principal components that are not affected by emissivity variations and pick out only the effects of temperature change are used for measurement.

(The principal components used for measurement are determined using a contact thermometer installed in the facility.)

Solution business

Solution business