Wet CO2 Mild Sour & HPHT

JFE-UHP™-15CR

JFE-UHP™-17CR

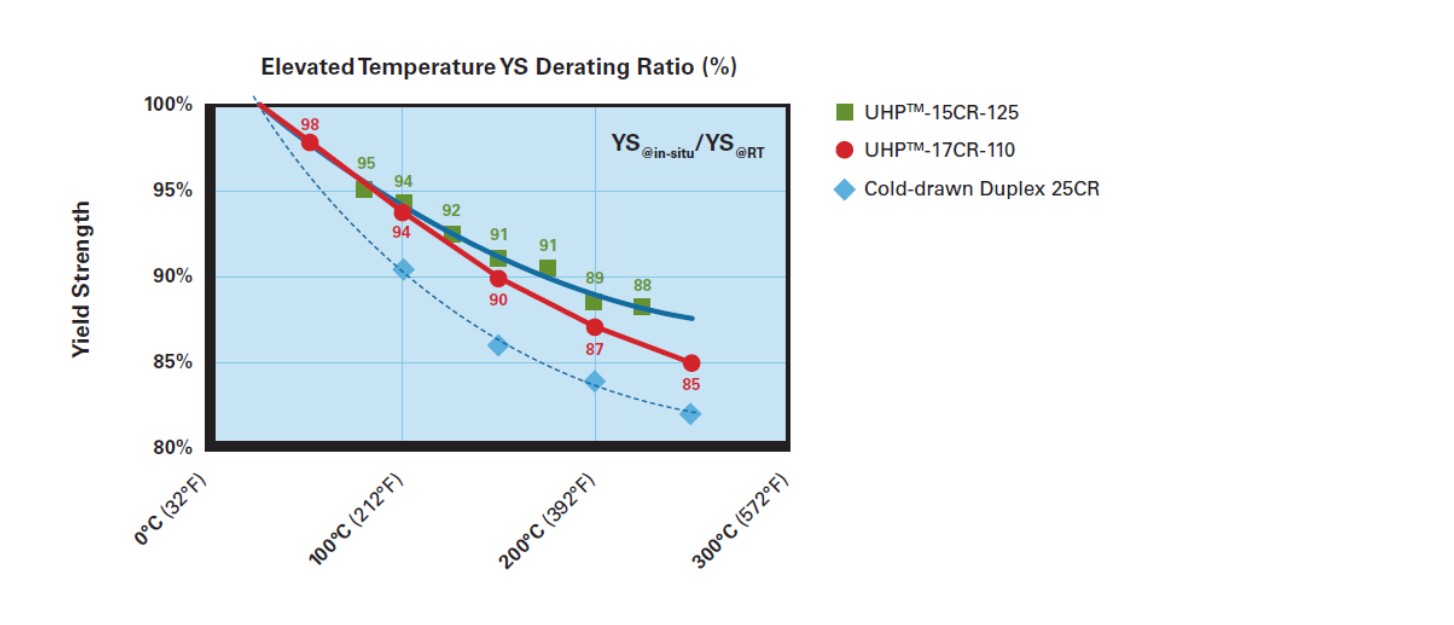

High demands for natural gas, deep water drilling and an increasing number of high pressure, high temperature (HPHT) wells has generated the need for high strength OCTG material with superior corrosion resistance at high temperatures. JFE-UHP™-15CR-125 / JFE-UHP™-17CR-110 is a material that has excellent corrosion resistance to acidizing conditions in corrosive environment. High yield strength and superior corrosion resistance are achieved even in the high temperature environment. The UHP materials are manufactured without cold drawing so it has a lower yield strength de-rating ratio at high temperatures compared to duplex material. Ultra-heavy wall pipe (>1-in. WT) and coupling stock (2.5-in. WT) size can be manufactured for HPHT wells. UHP materials with excellent corrosion resistance properties can be supplied with lower cost and shorter lead times than cold hardened duplex materials.

Process: Hot Rolled Seamless

Heat Treatment: Quenched and Tempered

| Grade | C | Mn | Mo | Cr | Ni | Cu | P | S | Si | Nb | W |

|---|---|---|---|---|---|---|---|---|---|---|---|

| JFE-UHP™-15CR-125 (UNS No. S42625) |

Max 0.05 | Max 1.8 | 1.5 - 3.5 | 14.0 - 16.0 | 5.0 - 7.0 | 0.5 - 1.5 | Max 0.03 | Max 0.005 | Max 0.50 | Max 0.20 | - |

| JFE-UHP™-17CR-110 (UNS No. S42825) |

Max 0.05 | Max 1.8 | 1.5 - 3.5 | 16.0 - 18.0 | 3.0 - 5.0 | Max 3.0 | Max 0.03 | Max 0.005 | Max 0.50 | Max 0.20 | Max 1.5 |

| Grade | Yield Strength | Tensile Strength | Elongation (%) | Hardness Max Avg. HRC |

|

|---|---|---|---|---|---|

| Min ksi (MPa) | Max. ksi (MPa) | Min ksi (MPa) | |||

| JFE-UHP™-15CR-125 | 125 (862) | 150 (1,034) | 135 (931) | API Formula | 37 |

| JFE-UHP™-17CR-110 | 110 (758) | 130 (896) | 120 (828) | 34 | |