JFE-80S

JFE-85S, 85SS

JFE-90S, 90SS

JFE-95S, 95SS

JFE-110S, 110SS

JFE-125S

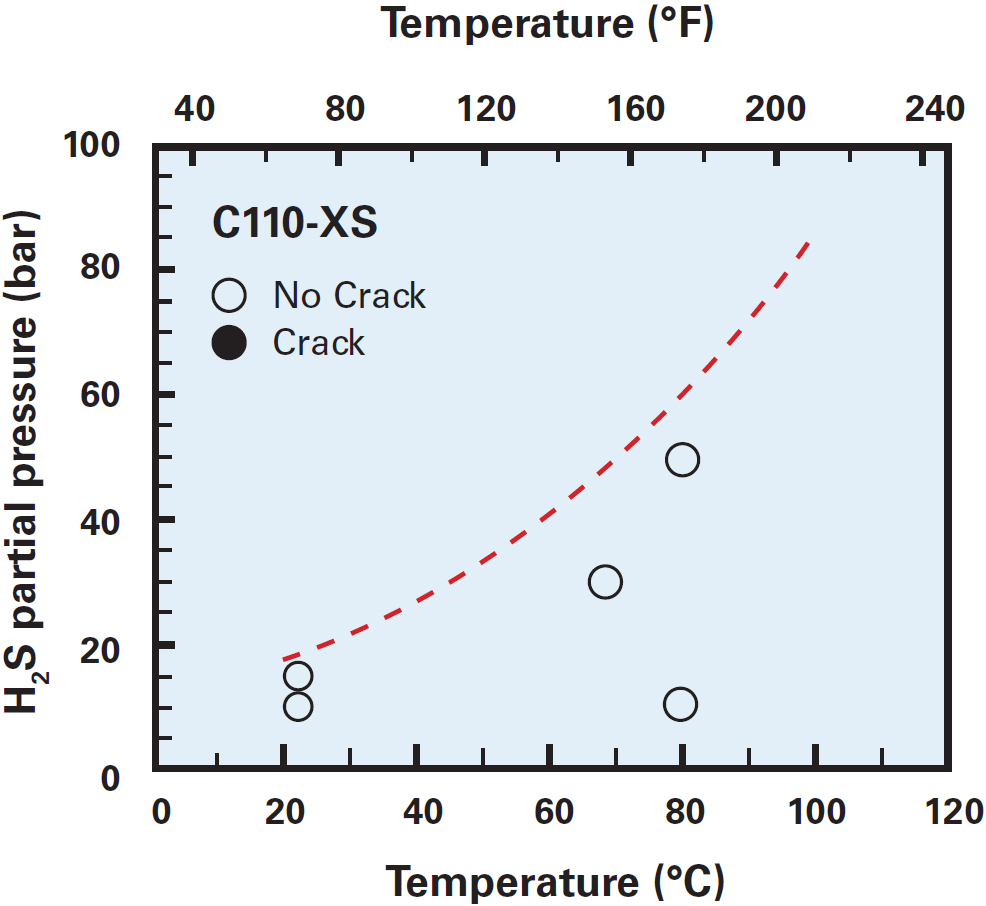

C110-XS

P110-MS

OCTG for sour wells must have improved resistance to sulfide stress cracking (SSC) in fluids containing H2S. Extensive research has led to the development of modified Cr-Mo steels for OCTG for sour wells. These steels feature both excellent hardenability and good temper resistance. Consequently, fine and homogenous tempered martensitic structure is obtained after tempering at higher tempering temperature. As a result, these enhanced grades have obtained excellent resistance to SSC with higher strength grades. These OCTG grades are subjected to stringent manufacturing and quality control.

The SSC-resistance of these grades has been thoroughly tested and qualified by major oil companies and is now widely used for sour gas and oil wells all over the world.

Process: Hot Rolled Seamless

Heat Treatment: Quenched and Tempered

| Grade | C | Mn | Mo | Cr | Ni | Cu | P | S | Si |

|---|---|---|---|---|---|---|---|---|---|

| JFE-80S JFE-85S JFE-85SS JFE-90S JFE-95S JFE-90SS |

0.15 - 0.35 | Max 1.35 | 0.05 - 1.10 | Max 1.60 | Max 0.10 | Max 0.30 | Max 0.020 | Max 0.010 | Max 0.35 |

| JFE-95S* JFE-95SS* |

Max 0.35 | Max 1.20 | 0.25 - 0.85 | 0.40 - 1.50 | Max 0.99 | - | Max 0.020 | Max 0.010 | Max 0.35 |

| JFE-110S** JFE-110SS** |

Max 0.35 | Max 1.20 | 0.25 - 0.85 | 0.40 - 1.50 | Max 0.99 | - | Max 0.020 | Max 0.010 | Max 0.35 |

| C110-XS | Max 0.35 | Max 1.20 | 0.25 - 0.85 | 0.40 - 1.50 | Max 0.99 | - | Max 0.020 | Max 0.005 | - |

| P110-MS | Max 0.35 | Max 1.00 | 0.15 - 1.10 | 0.80 - 1.60 | Max 0.10 | Max 0.30 | Max 0.020 | Max 0.010 | Max 0.35 |

| JFE-125S | Max 0.35 | Max 1.20 | 0.25 - 1.90 | 0.40 - 1.50 | Max 0.99 | - | Max 0.020 | Max 0.005 | - |

| Grade | Yield Str. | Tensile Str. | Elongation | Hardness | |

|---|---|---|---|---|---|

| Min KSI (MPa) | Max KSI (MPa) | Min KSI (MPa) | Min (%) | Max Avg. HRC | |

| JFE-80S | 80 (552) | 95 (655) | 95 (655) | API Formula | 22 |

| JFE-85S, 85SS | 85 (586) | 100 (689) | 95 (655) | 23 | |

| JFE-90S, 90SS | 90 (621) | 105 (724) | 100 (689) | 24 | |

| JFE-95S, 95SS | 95 (655) | 110 (758) | 105 (724) | 25 | |

| JFE-110S, 110SS | 110 (758) | 120 (828) | 115 (793) | 29 | |

| C110-XS | 110 (758) | 120 (828) | 115 (793) | 28* | |

| P110-MS | 110 (758) | 125 (862) | 125 (862) | 31 | |

| JFE-125S | 125 (862) | 140 (965) | 130 (896) | 36 | |

The mechanical properties (Strength, Hardness) of JFE-Series are more strictly controlled than API 5CT grade to achieve the greater sour resistance.