News Release

JFE Steel Corporation

JFE Steel Develops “GI JAZ™” High-lubricity GI Steel Sheet for Automobiles

— Dramatically improves press formability of hot-dip galvanized steel sheet —

Tokyo --- JFE Steel Corporation announced today that it has begun producing its recently developed “GI JAZ” high-lubricity hot-dip galvanized (GI) steel sheet, which offers dramatically improved press formability for use in automobile bodies. Commercial production for automobile manufacturers is now under way at JFE Steel’s West Japan Works.

GI steel sheet, which is hot-dip galvanized to coat its surface of steel substrate with pure zinc for strong corrosion resistance, is used mainly by European and American automobile manufacturers.

GI JAZ incorporates the high-lubricity technology used in “JAZ” (JFE Advanced Zinc) on GA steel sheet, which is heated after galvanizing to alloy the galvanized layer with iron of steel substrate to improve its spot-weldability and corrosion resistance after painting. JAZ has garnered a favorable reputation for its excellent press formability and is mass produced mainly for Japanese automobile manufacturers.

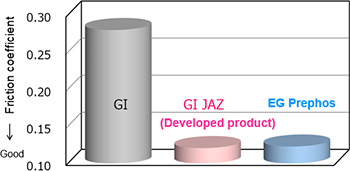

Most overseas automobile manufacturers use GI steel sheet or electrogalvanized (EG) steel sheet for rust-proof parts. Pre-phosphated EG steel sheet (EG Prephos), which is coated with an outer layer of zinc phosphate for high lubricity, is widely used because of its good press formability, but it incurs high processing costs for electroplating and zinc phosphate coating.

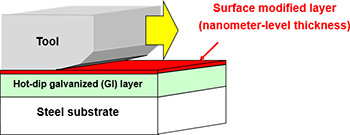

GI JAZ, which achieves formability equal to that of EG Prephos, also boasts a reduced friction coefficient because its surface modified layer , like that for JAZ (Fig. 1), reduces adhesion between the stamping tools and galvanized layer (Fig 2).

GI JAZ, similar to JAZ, allows automobile manufacturers greater freedom in vehicle structure and design, and helps them to stabilize press processes and reduce defects.

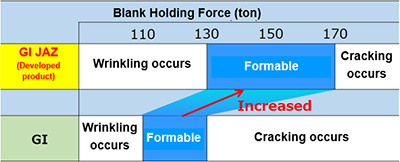

Press forming tests of GI JAZ were performed with an automobile fender (Fig. 3). The range of blank holding force that enables good press forming without any cracking or wrinkling was twice as wide as that for common GI steel sheets (Fig. 4). Furthermore, since GI JAZ’s surface modified layer is very thin as nanometer-level in thickness, JFE Steel has demonstrated that GI JAZ offers spot-weldability, bondability, phosphate treatability and coatability equal to that of common GI steel sheet, which are necessary performance to steel sheet for automotive applications.

JFE Steel, while building up its GI JAZ supply system, aims to develop other unique new products to satisfy customer needs going forward.

Fig. 1. Schematic of GI JAZ surface structure

Fig. 2. Comparison of friction coefficients

Fig. 3. Part made of “GI JAZ” press-formed with fender model tools

Fig. 4. Result of press formability evaluation using fender model tools

JAZ™ and GI JAZ™ are registered trademarks of JFE Steel Corporation.

About JFE Steel

JFE Steel Corporation, one of the world's leading integrated steel producers, was established through the consolidation of NKK Corporation and Kawasaki Steel Corporation in 2003. The company operates several steelworks in Japan and numerous branch offices and affiliates throughout the world. JFE Steel leverages world-class technologies and know-how to produce a wide range of products based on its “Only One, Number One” strategy of focusing on unique and best-in-class products. The company reported consolidated sales of 2,349 billion yen and consolidated crude steel output of 30.41 million tons in the fiscal year ended March 2017. For more information, please visit www.jfe-steel.co.jp/en.

# # #