Businesses

About JFE Steel Corporation

JFE Steel is a steelmaker engaged in the total steel-making process, taking iron ore raw material and turning it into final products. JFE Steel satisfies customers by producing steel under a corporate philosophy of "contributing to society with the world's most innovative technology." The company also contributes to environmental protection by developing reduced-impact ironmaking processes and high-performance steel materials.

About Iron

Iron is a fundamental material that supports industry and everyday life.

Iron is a wonderfully hard and strong material that can be processed flexibly for use in diverse applications, which is why it has been present in human civilization for millennia.

In the industrial revolution, iron played a vital role in key fields such as railroads, ships, construction and manufacturing. Steam engines and other power devices made with iron drove the development of modern civilization. In the 20th century, the widespread popularization of automobiles and consumer appliances would not have been possible without iron. Moreover, iron is highly recyclable and can be reused in any form over and over.

Currently accounting for approximately 90% of all metal products, iron underpins virtually every industry and--either directly or indirectly--is part of almost all aspects of our everyday lives.

Vehicles

Vehicles Shipbuilding

Shipbuilding Civil Engineering

Civil Engineering Construction

Construction Containers and Cans

Containers and Cans Consumer Electronics and Appliances

Consumer Electronics and Appliances Energy

Energy Industrial Machinery

Industrial Machinery

Hidden Potential: Iron Continues to Evolve

Iron's association with ancient civilization can obscure the fact that it has evolved into an advanced material produced with cutting-edge technologies. Nonstop research and development and continuously improving production technologies are creating highly advanced steel products in response to industry's insatiable demand for ever-stronger and more processable materials. Continued technological innovation is expected to discover still-hidden potential within steel to meet increasingly stringent performance and environmental demands.

Going forward, iron's perpetual evolution will play a role in shaping our future.

Production Bases

JFE Steel's production bases in Japan comprise large coastal ironworks in the eastern and western parts of the country, plus the Chita Works specializing in pipes and the Sendai Works for steel rods and wire materials. Every facility is equipped with cutting-edge technical capabilities for the exceptionally efficient production of high-quality steel products.

West Japan Works

The West Japan Works is one of the world's most advanced steel mills and one of the largest, covering a cumulative area measuring 25,100 hectares. Its production system boasts continuous, synchronized processes for ironmaking, steelmaking and rolling, and the flexibility and efficiency to meet the needs of even the most demanding customers. As the core steelworks for JFE Steel, the West Japan Works will continue to serve as a leading edge of the global steel industry.

East Japan Works

The East Japan Works is an urban-style steel mill that combines the Keihin Works, Japan's first private steelwork, located in the Tokyo-Yokohama (Keihin) area, and the Chiba Works, the first integrated steel production facility established in Japan after World War II. The East Japan Works has continued to expand its size and upgrade its layout to meet increasingly sophisticated and diverse demands. Today, it boasts advanced steelmaking technologies and facilities as well as renowned systems for environmental protection. The East Japan Works stringently conserves resources and energy, and is a leader in the recycling of waste plastics for blast furnace feed. Together with JFE Steel's Nishinomiya stainless steel manufacturing plant, the East Japan Works is a top example of how urban steel mills can coexist in harmony with the environment and their host communities.

Chita Works

The Chita Works specializes in the production of steel pipes and tubes, boasting the largest selection of steel pipes produced by any single plant in the world. Its unchanging mission is to develop steel pipes with the world's most advanced and innovative technologies.

Sendai Works

The Sendai Works specializes in manufacturing steel bars and wire rods. Its integrated production system encompasses strip mills and a reduced-impact eco-arc electric furnace that melts scrap for production as new steel. Rational production-management measures ensure thorough control of all processes for the production of steel bars and wire rods of exceptional quality.

Research and Development

The East Japan Works, West Japan Works, Chita Works and Sendai Works Steel each has its own research laboratory for the development of world-class technologies.

Steel Research Centers

JFE Steel proudly operates among the world's most advanced laboratories for steel research. JFE researchers innovate manufacturing technologies and products that expand the possibilities of steel-based materials. Technologies and know-how that originate in these facilities are further applied towards chemistry and broader research and development related to iron and the environment.

Main Products

JFE Steel has leveraged it advanced technical capabilities to develop a diverse lineup of high-quality steel products that meet highly demanding needs.

Sheets

JFE Steel produces a range of steel sheets by hot rolling slabs, cold rolling hot-rolled sheets, galvanizing steel sheets, tin plating steel sheets, and other processes. The company's high-quality steel sheets are used in automobiles, electrical products, construction, office equipment, containers and many other fields.

Plates

JFE Steel offers an abundant lineup of steel plates, including some that are the world's largest of their type. Unique, high-performance steel plates are manufacured with powerful rolling machines and on-line facilities for accelerated cooling. Steel plates from JFE Steel are highly trusted matericals for diverse applications, including shipbuilding, construction, bridge building, boilers and pressure containers, industrial machinery and more.

Shapes and Spiral Pipes

Shapes and spiral pipes from JFE Steel are used in construction, civil engineering and shipbuilding, and the company additionally provides customers with design and construction know-how. They include steel H-beams, steel sheet piles, angled steel, grooved steel, steel I-beams and rails, and along with steel rods, they have enjoyed strong demand for many years.

Pipes

JFE Steel not only makes steel pipes for converntional fields, such as structures and civil engineering, it also produces high-performance oil well pipes, line steel pipes and boiler tubes capable of withstanding the harsh conditions of energy production. Going forward, JFE Steel is committed to meeting demanding gobal needs as a leading producer of steel pipes.

Electrical Steel

Electric steel sheets perform a key role by converting electricity into magnetic forces to generate power. The demand for high-performance electrical equipment capable of low power consumption has been increasing to help reduce CO2 emissions. One of the world's few manufacturers with a full lineup of electric steel sheets, JFE Steel is noted for combining high quality and environmental sensitivity.

Stainless Steel

In the category of stainless steel, which is used widely in industry due to its excellent corrosion resistance, JFE Steel meets complex needs with a comprehensive lineup of thin to thick stainless sheets. These include the world's only chromium (ferrite or martensite based) thin stainless sheets. Additionally, JFE Steel has earned global acclaim for its stainless steel manufacturing technology.

Bars, Wire Rods and Welding Materials

JFE Steel produces bars, wire rods and welding materials at Kurashiki in west Japan and at Sendai in east Japan, allowing customers to select blast furnace materials and electric arc materials best suited to their specific needs. The JFE Steel lineup covers a full complement of high-quality products for automobiles, machinery, bearings and other applications.

Iron Powders

JFE Steel's highly respected iron powder products are used in a broad scope of applications, including in powder metallurgy primarily for automobiles, as well as for hand warmers, welding rods, gas cutting, deoxidizers and chemical reactions.

Titanium

Titanium is a lightweight, high-specific-strength material that is extra corrosion resistant, making it ideal for use in the chemical industry. Titanium does not change over time and is recyclable, so it also is a non-polluting ecofriendly metal. Thick titanium sheets from JFE Steel can be found in fields such as aerospace, chemistry, seawater desalination and oceanic development.

Slag

JFE Steel makes slag products by processing slag, a byproduct of steel manufacturing, for use in diverse applications. Slag products are also valued as recycled materials that reduce environmental burdens by helping to conserve resources and save energy.

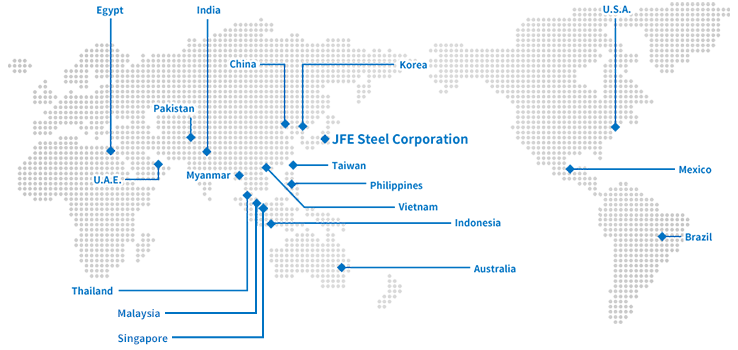

Overseas Expansion

JFE Steel's medium- to long-term vision is to be a global steel supplier that constantly creates new value to grow together with its customers. To achieve this vision, one of the key strategies is to aggressively expand the company's business scale, including by statisfying growing demands in emerging nations. So far, the Japanese steel industry has focused largely on exporting products from Japan. However, to compete leading steel manufacturers, JFE Steel has determined that it must upgrade its global service and support offerings. Accordingly, the company is now establishing a more global network by expanding production and logistics operations directly in markets overseas.

Global Production & Sales Bases

Globalization through Exports and Local Production